User Manual for HBF Freezers

Beverage-Air

Rev. 08/20

Beverage-Air

18

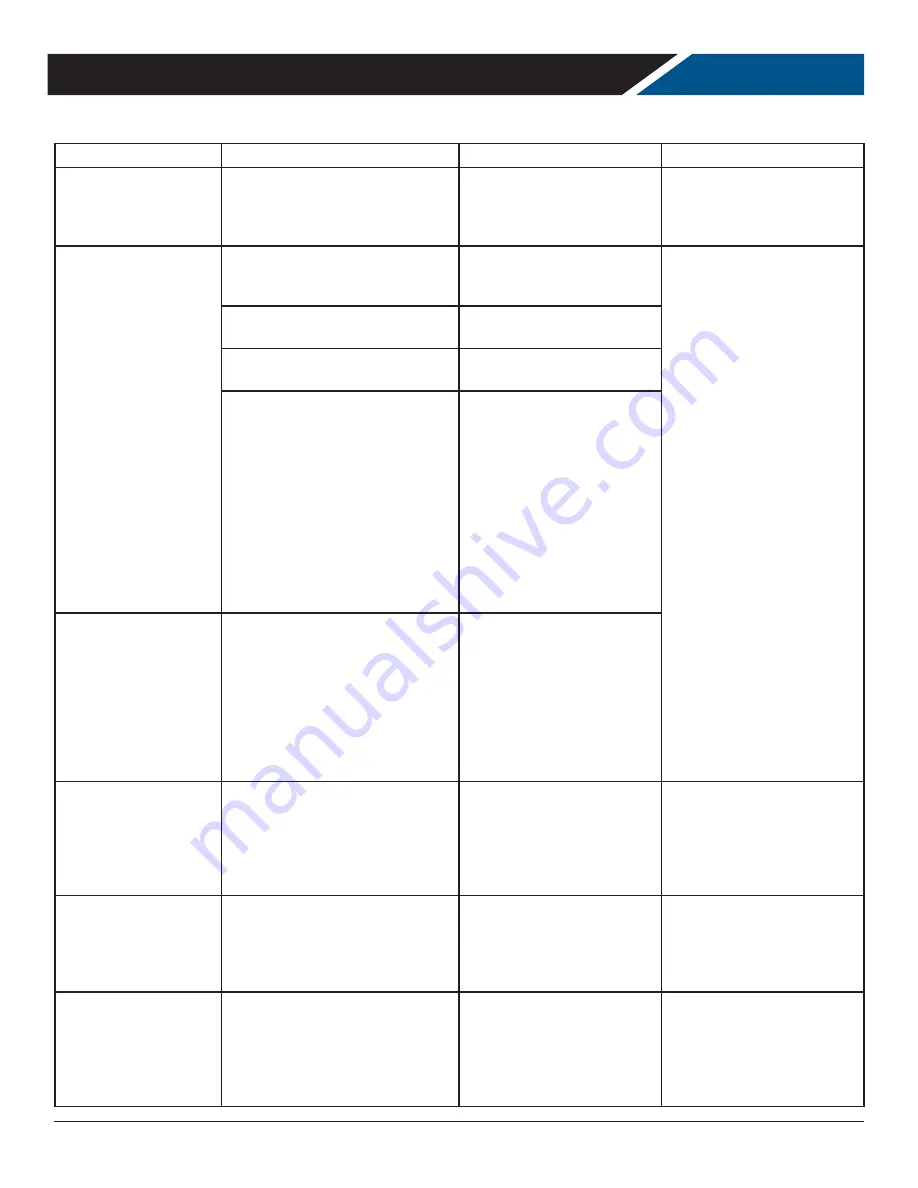

Cleaning Needed

Cleaning Agent

Method of Application

Affect on Finish

Smears and fingerprints

Areal 20, Lac-O-Nu, Lumin Wash

O’Cedar Cream Polish, Stainless

Shine.

Rub with cloth as directed

on the package.

Satisfactory for use on all

finishes.

Provides barrier film to

minimize prints.

Stubborn Spots and

Stains, Baked-On

Splatter, and Other

Light Discolorations

Allchem Concentrated Cleaner.

Apply with damp sponge or

cloth.

Rub with damp cloth.

Use in direction of polish lines

on No. 4 (polished) finish. May

scratch No.

2 (mill) and Nos. 7 and 8

(polished) finishes.

Samae, Twinkle or Cameo Copper

Cleaner

Rub with damp cloth.

Grade FFF Italian pumice, whiting,

or talc.

Rub with dry cloth.

Liquid NuSteel

Paste NuSteel or DuBois Temp.

Copper’s Stainless Steel Cleaner

Revere Stainless Cleaner

Household cleansers, such as

Old Dutch, Lighthouse, Sunbrite,

Wyandotte, Bab-O, Gold Dust,

Sapolio, Bon Ami, Ajax, or Comet

Grade F Italian Pumice, Steel

Bright, Lumin Cleaner, Zud,

Restore, Sta-Clean, or Highlite.

Penny-Brite or Copper-Brite.

Use small amount of cleaner.

Rub with dry cloth using a

small amount of cleaner.

Apply with damp sponge or

cloth.

Rub with a damp cloth. May

contain chlorine bleaches.

Rinse

thoroughly after use.

Rub with a damp cloth.

Rub with a dry cloth using a

small amount of cleaner.

Heat tint or

discoloration

Penny-Brite or Copper-Brite.

Past NuSteel, DuBois Temp,

or Tarnite. Revere Stainless Steel

Cleaner. Allen Polish, Steel Bright,

Tenacious Deposits,

Rusty Discolorations,

Industrial

Atmospheric Stains Wyandotte,

Bab-O or Zud.

Rub with a dry cloth.

Rub with a dry cloth or stain-

less steel wool.

Apply with damp sponge or

cloth.

Rub with a damp cloth.

Burnt-On Foods and

Grease Fatty Acids,

Milkstone (where

swabbing or rubbing

is not practical)

Easy-Off, De-Grease-It, 4 to 6%

hot solution of such agents as

trisodium phosphate or sodium

tripolyphosphate or 5 to 15% caustic

soda solution

Apply generous coating. Allow

to stand for 10-15 minutes.

Rinse.

Repeated application may be

necessary.

Excellent removal, satisfactory

for use on all finishes.

Tenacious Deposits,

Rusty Discolorations,

Industrial

Atmospheric Stains

Oakite No. 33, Dilac Texo 12, Texo NY,

Flash-Klenz, Caddy Cleaner,

Turco Scale 4368 or Permag 57.

Swab and soak with clean

cloth.

Let stand 15 minutes or more

according to directions on

package, then rinse and dry.

Satisfactory for use on all

finishes

Hard Water Spots

and Scale

Vinegar.

5% oxalic acid, 5% sulfamic acid, 5 to

10% phosphoric acid, or Dilac, Oakite

No. 33, Texo 12, Texo N.Y.

Swab or wipe with cloth. Rinse

with water and dry.

Swab or soak with cloth. Let

stand 10-15 minutes. Always

follow with neutralizer rinse,

and dry.

Satisfactory for all finishes.

Satisfactory for all finishes.

Effective on tenacious deposits

or where scale

has built up.

METHODS FOR CLEANING STAINLESS STEEL