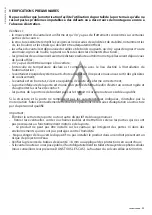

USER WARNINGS ( I )

WARNING! Important safety instructions�

Carefully read and comply with the Warnings

and Instructions that come with the product as

improper use can cause injury to people and

animals and damage to property� Keep the

instructions for future reference and hand them

on to any new users�

This product is meant to be used only for the

purpose for which it was explicitly installed�

Any other use constitutes improper use and,

consequently, is hazardous� The manufacturer

cannot be held liable for any damage as a result

of improper, incorrect or unreasonable use�

GENERAL SAFETY

Thank you for choosing this product. The Company

is confident that its performance will meet your

operating needs.

This product meets recognized technical standards

and complies with safety provisions when installed

correctly by qualified, expert personnel (professional

installer).

If installed and used correctly, the automated system

will meet operating safety standards. Nonetheless,

it is advisable to observe certain rules of behaviour

so that accidental problems can be avoided:

- Keep adults, children and property out of range of

the automated system, especially while it is moving.

- Do not allow children to play or stand within range

of the automated system.

- This automated system can be used by children

older than 8 but is not intended to be used by

children or by individuals with reduced mental,

physical or sensory abilities, or by individuals

without adequate know-how unless supervised

or instructed on equipment use by the individual

in charge of their safety.

- Children should be supervised to ensure they do

not play with the equipment. Do not let children

play with the fixed controls. Keep remote controls

out of reach of children.

- Do not work near hinges or moving mechanical parts.

- Do not hinder the leaf's movement and do not

attempt to open the door manually unless the

actuator has been released with the relevant release

knob.

- Keep out of range of the motorized door or gate

while they are moving.

- Keep remote controls or other control devices out

of reach of children in order to avoid the automated

system being operated inadvertently.

- The manual release's activation could result

in uncontrolled door movements if there are

mechanical faults or loss of balance.

- The breakage or wear of any mechanical parts of

the door (operated part), such as cables, springs,

supports, hinges, guides…, may generate a hazard.

Have the system checked by qualified, expert

personnel (professional installer) at regular intervals

according to the instructions issued by the installer

or manufacturer of the door.

- When cleaning the outside, always cut off mains

power.

- Keep the photocells' optics and illuminating

indicator devices clean. Check that no branches

or shrubs interfere with the safety devices.

- Do not use the automated system if it is in need of

repair. In the event the automated system breaks

down or malfunctions, disconnect the system at the

mains; do not attempt to repair or perform any other

work to rectify the fault yourself and instead call in

qualified, expert personnel (professional installer)

to perform the necessary repairs or maintenance.

To allow access, activate the emergency release

(where fitted).

- If any part of the automated system requires direct

work of any kind that is not contemplated herein,

employ the services of qualified, expert personnel

(professional installer).

- At least once a year, have the automated system, and

especially all safety devices, checked by qualified,

expert personnel (professional installer) to make

sure that it is undamaged and working properly.

- A record must be made of any installation,

maintenance and repair work and the relevant

documentation kept and made available to the

user on request.

- Failure to comply with the above may result in

hazardous situations.

SCRAPPING

Materials must be disposed of in accordance

with the regulations in force. Do not dispose of

the used equipment or batteries in domestic

waste. You are liable for returning your

electric or electronic waste to a collection

site dedicated to their recycling.

Anything that is not explicitly provided for in

the user manual is not allowed� The operator's

proper operation can only be guaranteed if the

instructions given herein are complied with� The

Company cannot be held liable for damage caused

by the failure to comply with the instructions

featured herein�

While we will not alter the product's essential

features, the Company reserves the right, at any

time, to make those changes deemed necessary

to improve the product from a technical, design

or commercial point of view, and will not be

required to update this publication accordingly�