158

•

Check the opening and closing manoeuvres using the controls.

•

Check the control unit’s electronic logic in normal (or customised)

operation.

12) USE OF THE AUTOMATION

Since the automation may be remote controlled either by radio or a Start

button, it is essential that all safeties are checked frequently.

Any malfunction should be corrected immediately by a qualified specialist.

Keep children at a safe distance from the field of action of the automation.

13) THE CONTROLS

With the automation the gate has a power driven opening and closing. The

controls can come in various forms (i.e. manual, remote controlled, limited

access by magnetic badge, etc.) depending on needs and installation

characteristics. For details on the various command systems, consult the

specific instruction booklets.

Anyone using the automation must be instructed in its operation and

controls.

14) MAINTENANCE

When carrying out maintenance operation on the controller, disconnect it

from the mains power supply. The actuator does not require periodical

maintenance operations.

•

Check the safety devices of the gate and automation.

•

Periodically check the pushing force and correct the value of the electric

torque in the control board if necessary.

•

In case of unsolved operation failures, disconnect the unit from the

mains power supply and ask for the intervention of qualified personnel

(installer).

When the unit is out of order, activate the manual release to perform

manual opening and closing manoeuvres.

15) NOISE

The aerial noise produced by the gearmotor under normal operating

conditions is constant and does not exceed 70dB(A).

16) SCRAPPING

Materials must be disposed of in conformity with the current regulations.

In case of scrapping, the automation devices do not entail any particular

risks or danger. In case of recovered materials, these should be sorted out

by type (electrical components, copper, aluminium, plastic etc.).

17) DISMANTLING

When the automation system is disassembled to be reassembled on

another site, proceed as follows:

•

Disconnect the power supply and the entire electrical installation.

•

Remove the gearmotor from its fixing base.

•

Disassemble the control panel, if separate, and all installation

components.

•

In the case where some of the components cannot be removed or are

damaged, they must be replaced.

18) TROUBLES AND SOLUTIONS

18.1) Incorrect operation of gearmotor

a) Check for the presence of power supply to the gearmotor using a

suitable instrument after opening or closing commands have been

given.

b) If the moving direction of the leaf is opposite to the right one, invert the

motor running connections (motor +red/ motor - black).

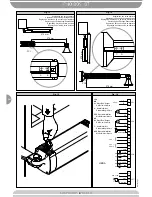

c) Should the gate stop and hit the ground stopping device and the actuator

reverse its moving direction, it means that the limiting devices have not

been adjusted correctly. If this happens on the opening stopping device,

move the opening limiting device towards the hinge of the gate until the

correct position is found(see adjustment of the limiting devices).

If, on the contrary, this happens on the closing stopping device, move

the closing limiting device towards the stem plug until the correct

position is found (see adjustment of the limiting devices).

18.2) Incorrect operation of the electrical accessories

All control and safety devices can cause, in case of failure, malfunctioning

or stoppage of the automation.

To identify the failure, it is advised to disconnect all the devices of the

automation one by one until the one causing the problem is found.

After fixing or replacing the defective device, reset all the devices previously

disconnected. Refer to the relevant instruction manual for all the devices

installed on the automation.

WARNINGS

Correct controller operation is only ensured when the data contained

in the present manual are observed. The company is not to be held

responsible for any damage resulting from failure to observe the

installation standards

and the instructions contained in the

present manual.

The descriptions and illustrations contained in the present manual

are not binding. The Company reserves the right to make any alterations

deemed appropriate for the technical, manufacturing and commercial

improvement of the product, while leaving the essential product

features unchanged, at any time and without undertaking to update

the present publication.

D811316_02

PHOBOS BT

PHOBOS BT

AUTOMATION FOR SWING GATES

AUTOMATION FOR SWING GATES