INSTALLATION MANUAL

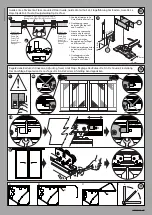

10) FLOOR-MOUNTED DOOR GUIDE (Fig. M)

- Framed doors (Fig. M Rif. 3)

- Glass doors (Fig. AE)

- Breakout doors

See the relevant instruction manual for their assembly.

11) ADJUSTING TRAVEL LIMIT STOPS (Fig. N)

If the positions of the RH and LH travel limit stops (parts. 10 Fig. AA) need to be

fine-tuned, carefully check the travel and alignment of the runners carrying the

doors.

It is important to remember that the position of the travel limit stops also deter-

mine the control board’s self-learning.

----------------------------------------------------------

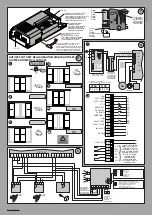

12) ARIA CONTROL BOARD

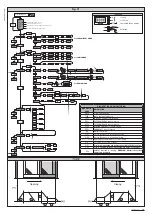

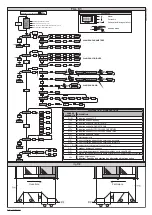

12.1) TERMINAL BOARD WIRING (Fig. P)

WARNINGS - When performing wiring and installation, refer to the

standards in force and, whatever the case, apply good practice prin-

ciples.

The wires carrying a very low safe voltage (24V) must be kept physically separate

from low-voltage wires, or they must be suitably insulated with at least 1mm of

additional insulation. Wires must be secured with additional fastening near the

terminals, using devices such as cable clamps.

13.1) FACTORY CONNECTIONS (Fig. Q Rif. 1)

TERMINAL

DESCRIPTION

JP2-JP4

Power supply unit wiring

JP2= brown

JP4= white/blue

JP7-JP8

Gearbox wiring

JP7=brown

JP8=white/blue

JP12

Encoder wiring

JP19

Solenoid lock wiring

13.2) USER CONNECTIONS (Fig. P - Q)

TERMINAL

DESCRIPTION

L

PHASE

N

NEUTRAL

EARTH

JP18

Universal palmtop programmer connector

JP10

Connector for additional optional boards

1

Controllers common

2

OPENING PHOTOCELL (NC) input

3

CLOSING PHOTOCELL (NC) input

4

STOP (NC) input

5

EXT. RADAR control (NO) input

6

INT. RADAR control (NO) input

7

OPEN KEY (NO) input

8

EMERGENCY input

9

Control common

10

OPENING PHOTOCELL FAULT (NO) input

11

CLOSING PHOTOCELL FAULT (NO) input

12-13

24V~ VSAFE 180mA max output

Power supply to devices with checking function.

14-15

Serial RS485.

14 = A

15 = B

Connection to external programming devices.

Controllers common

Connection of remote door in cage mode

16-17

24V~ 500mA max output

Power supply to radar controls, photocells or other devices.

18-19-20

“Door status” output

18 = NO (voltage-free contact)

19 = COM (voltage-free contact)

20 = NC (voltage-free contact)

21-22-23

“Alarm” output

21 = NO (voltage-free contact)

22 = COM (voltage-free contact)

23 = NC (voltage-free contact)

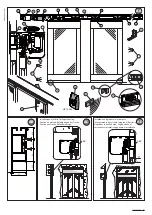

14) CENTRAL PROGRAMMING (Fig.C1)

14.1) PARAMETER MENU

(

PARA

)

(TABLE “A” PARAMETERS)

14.2) LOGIC MENU (

logic

)

(TABLE “B” LOGIC)

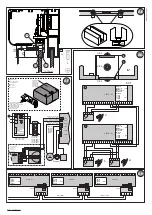

14.3) RADIO MENU (

RADIO

)

Logic

Description

add open

Add Start Open

associates the desired key with the Open command

add ey

Add Open Key

associates the desired key with the Open Key command

read

Read

Checks a key of a receiver and, if memorized, returns the

number of the receiver in the memory location (from 01 to

63) and number of the key (T1-T2-T3 or T4).

erase 64

Erase List

WARNING!

Erases all memorized remote controls from

the receiver’s memory.

cod RX

Read receiver code

Displays receiver code required for cloning remote controls.

k

ON =

Enables remote programming of cards via a previously me-

morized W LINK transmitter. It remains enabled for 3 minutes

from the time the W LINK remote control is last pressed.

OFF=W LINK programming disabled.

- IMPORTANT NOTE: THE FIRST TRANSMITTER MEMORIZED MUST BE

IDENTIFIED BY ATTACHING THE KEY LABEL (MASTER).

In the event of manual programming, the first transmitter assigns the RECEIVER’S

KEY CODE: this code is required to subsequently clone the radio transmitters.

The Clonix built-in on-board receiver also has a number of important advanced

features:

• Cloning of master transmitter (rolling code or fixed code)

• Cloning to replace transmitters already entered in receiver

• Transmitter database management

• Receiver community management

To use these advanced features, refer to the universal handheld programmer’s

instructions and to the CLONIX Programming Guide, which come with the uni

-

versal handheld programmer device.

14.4) LANGUAGE MENU (

language

)

Used to set the programmer’s language on the display.

14.5) DEFAULT MENU (

default

)

Restores the controller’s default factory settings.

14.6) AUTOSET MENU (

Autoset

)

(Fig. R)

When this function is activated, the parameters relating to door movement and

obstacle detection are automatically set to their optimum values:

- Running speed during opening

- Running speed during closing

- Opening slow-down distance

- Closing slow-down distance

- Opening deceleration distance

- Closing deceleration distance

- Acceleration

- Deceleration

- Opening torque

- Closing torque

3 complete cycles are performed as the autoset function is run.

While autoset is running, the anti-crush function is not active.

The door must not be stopped or slowed down at any point during its

travel while autoset is running.

15) CENTRAL OPERATION:

15.1) DOOR OPERATION MODE

Mode 0) Standard operation door (Fig. S)

Reaction to commands:

- Open key:

Opens at high speed, closes at low speed. Opens and activates an Open-key operation,

if activated while the door is open, it sets clear time to zero; reopens if activated during

closing. With the door open, the clear-time countdown is active. During closing, pho

-

tocells stop movement instead of reversing. Once they are cleared, closing is resumed

following the TCA countdown. During the Open-key operation, the radars are not

active

- External radar:

Performs a high-speed cycle. Opens, with the door open, it triggers the auto

-

matic closing time; if activated while the door is open, it sets automatic closing

time to zero. If clear time was active - activated by an Open-key operation - with

the door open, this time is converted into automatic closing time. Following

the automatic closing time, the door closes. During closing, it causes the door

to open again.

D811590 00100_01

VISTA SL

- 21