BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

Storage

Contamination caused by dust or dirt can affect the gun’s efficiency. Wrap up the spray gun with a

piece of plastic or kitchen foil before you store it so that it is secured against any type contamination

and later damage.

Maintenance / Cleaning

The spray gun does only work properly when it is kept clean. Clean your spray gun carefully and

thoroughly after each use. Follow these steps:

•

Clean your tool by using paint thinner. Run the gun with paint thinner instead of paint to clean its

interiors.

•

The nozzle thread and all moving parts should be lubricated with acid-free oil.

•

Never use hydrocarbon halogen solvents to clean the gun. This may cause a chemical reaction.

•

Never dip the gun completely into paint thinner.

CAUTION

Disconnect the spray gun from its air supply before maintenance or cleaning!

LUBRICATION & MAINTENACE

Only operate with compressed air systems that have the correct air pressure and sufficient air volume

(L / min) for this tool.

Drain the compressed air system before each use.

Water in the compressed air line leads to tool destruction and loss of performance.

Clean or replace air filters at the specified intervals.

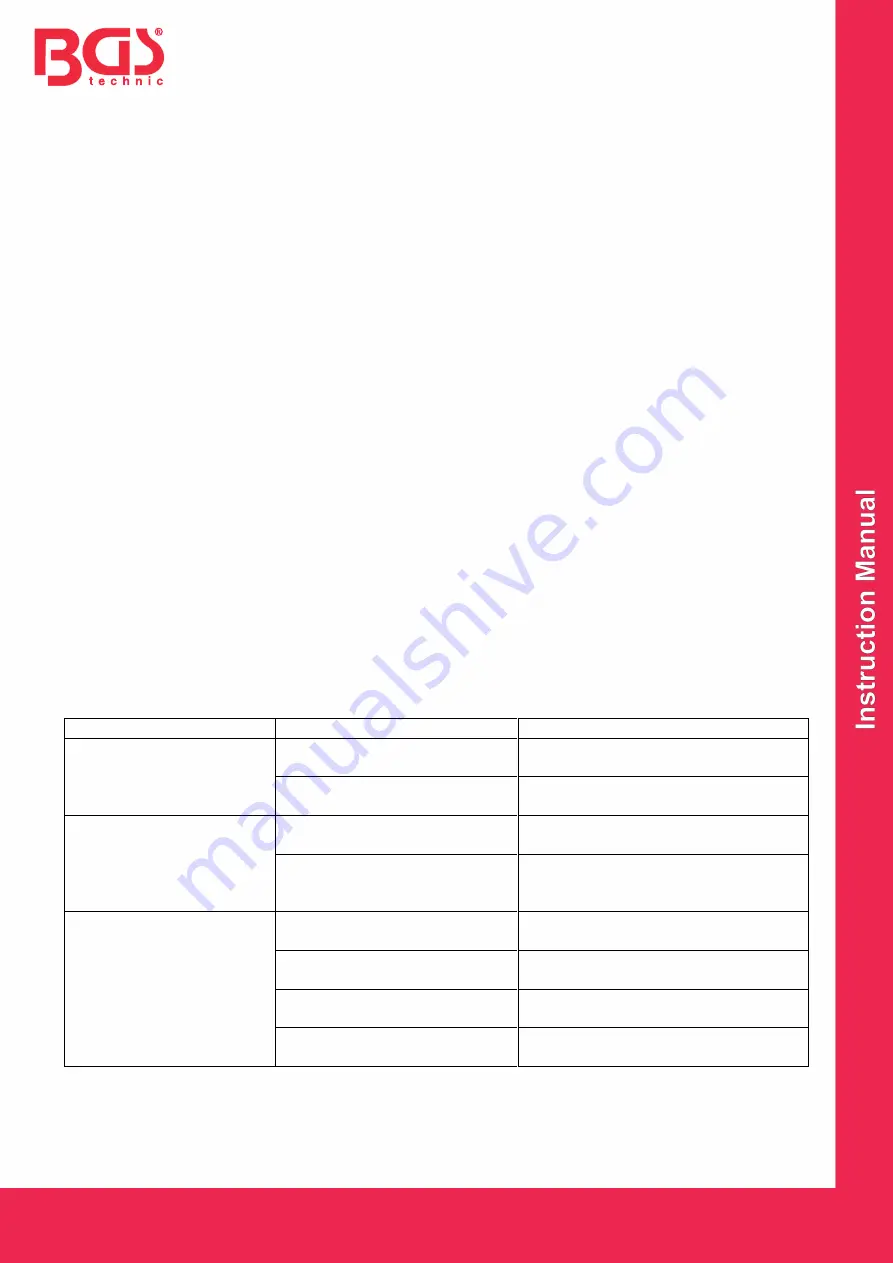

TROUBLESHOOTING

Error

Possible cause

Help

Too little or no pressure in

the tool

The pressure reducer has not

been opened

Check the pressure reducer’s setting

– open it if necessary

The air hose leaks

check all connections and seal

leaking components if necessary

No air in the tool

The nozzle is jammed

Clean lean the nozzle and remove

residual paint/varnish

The air supply is being blocked

Check the air supply and the setting

of the pressure reducer – open it if

necessary

Unsteady spray jet

The paint has not been

thinned enough

Thin down the paint according to its

manufacturer’s recommendation

Too little paint in the cup

Fill up the cup with paint (watch its

min./max. capacity)

Too high or too low operating

pressure

Adjust the operating pressure with

the pressure reducer

Dirt and/or residual paint block

the nozzle

clean the nozzle and/or replace it if

necessary