8

Strictly perform installation, set-up, maintenance, cleaning

and transportation with the motor switched off and the tool

firmly secured against accidental operation.

The user shall strictly comply with these operation, set-up, maintenance, repair

and troubleshooting instructions in order to assure safe operation and no dama-

ges to the equipment. Moreover we recommend to let the machine be run only

and strictly by trained and skilled staff who must be familiar with the applicable

occupational safety and health administration rules as well as applicable transpor-

tation rules. Incorrect use of the splitter can cause serious injury or death. Make

sure that full compliance is assured at all times with the general safety and health

rules on the workplace as well as the applicable local traffic rules.

No person under school leaving age of 18 should operate a circular saw. Ho-

wever, young people in age of 16 or slightly more may work on the machine

providing that they received adequate training, that they carry all due perso-

nal protection safeties and that an adult supervisor keeps standing nearby.

Machine instability can result in injury or severe damages. To ensure stability

during operation make sure to choose a flat, dry floor free from any tall grass,

brush or other interferences.

The working area around the machine must be kept as clear as possible

from surrounding tripping obstacles and slippery foundation floors should

be duly treated (do not use saw dust or wood ash for this purpose).

Make sure that the equipment stands on a safe stable foundation.

Following precautions must be taken at all times

• NEVER use your log splitter at night or without sufficient illumination.

• NEVER operate your log splitter on slippery, wet, muddy, or icy sur-

faces and ensure that a wide but confined area is available around the

machine and assure maximum working freedom.

• NEVER operate the machine without wearing steel-toed shoes, tight-

fitting gloves and tear-resistant work cloths.

• NEVER remove from your log splitters the safety tools and devices

mounted on the machine by the manufacturer.

• NEVER leave the splitter unattended while the engine is running.

Always assure compliance with safety, protection and accident pre-

vention rules as well as general road and traffic rules in the country

of use.

Operators should always wear personal protection cloths, steel-to-

ed safety shoes, snug-fitting tear-resistant work cloths, safety gloves

earplugs and safety goggles. Site must be free of slippery surfaces

and tripping obstacles. Make sure that all access ways are properly

maintained so that wood can be safely delivered, loaded and shipped.

4. SAFETY

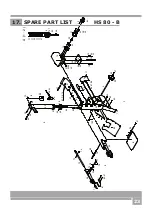

Summary of Contents for HS 80-2 B

Page 27: ...27...