General Information

5

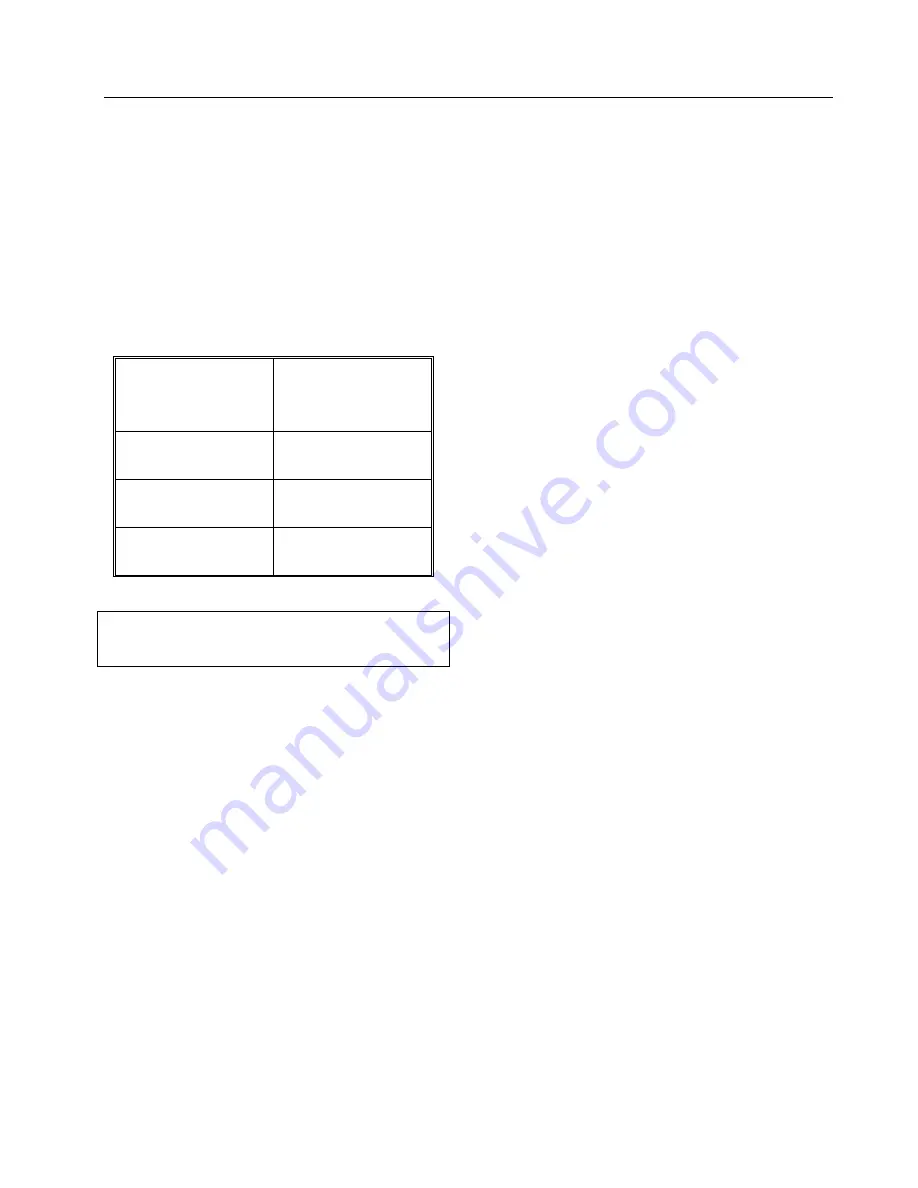

Operational Life

The equipment is designed and tested for a

useful life of seven (7) years or

10 000 transfers—whichever comes first—

subject to preventative maintenance as

specified in the “Disinfection, Cleaning and

Maintenance” section in this manual. Time

equivalence between the number of transfers

versus the number of years is made clear in

the table below.

Transfers per Day

Years

(10,000 transfers)

4 7

6 4.5

8 3.5

WARNING: The manufacturer cannot ensure

full safety for a floor lift or an accessory of

which the life span has been exceeded.

The operating life of this equipment

corresponds directly to the safe operating time

period before a complete overhaul is required.

Aging of the unit, frequency of use (transfers

per day), the weight of the patient and

maintenance frequency are factors that have

an impact on the lift’s life span. A transfer is

defined as the displacement of a patient from

one point to another. A transfer cycle includes

a lifting and a descending action.

The expected life for other consumable

products, such as batteries, fuses, lamps,

slings, straps and cords is dependent upon the

care and usage of the equipment concerned.

Consumables must be maintained in

accordance with published

Instructions for

Use

and the “Preventive Maintenance

Schedule”.

Equipment Identification

The unit's identification number

(specification, model, serial number) appears

on a silver nameplate attached to the lift’s

mast.

Verifying the Package Contents

Upon receipt of the equipment, verify it

against the packing list to ensure it is

complete and inspect the equipment for

possible damage due to shipping. If there is

any damage, notify the carrier immediately to

file a claim. Provide complete information

concerning damage claims or shipping errors

to your local BHM Medical representative.

Include all equipment identification numbers

and group part numbers (if any) as described

above along with a full description of

damaged parts.

Policy on Number of Staff Members

Required for Patient Transfer

BHM Medical’s passive and active series of

lifts are designed for safe usage with one

caregiver. There are circumstances, such as

combativeness, obesity, contractures etc. of

the patient that may dictate the need for a

two-person transfer. It is the responsibility of

each facility or medical professional to

determine if a one or two person transfer is

more appropriate, based on the task, patient

load, environment, capability, and skill level

of the staff members.