ENGLISH

17

4.5.4 Stirrer filling

Use only stirrers specifically designed for automatic dispenser ma

-

chines.

- remove the metal weight from the column device (

Fig. 4.19

)

- Insert spoons, with their packaging band, into the upper section of the

column and place them on the bottom, then cut and remove the band

(Fig.4.20).

– Check that the spoon are cut burr-free, that they are not bent and that

they are all placed horizontally.

- complete filling and replace the small weight (

Fig. 4.21

)

– with a cloth soaked with the solution clean the whipper assembly base

(Fig.4.10)

– the parts must soak in the solution for the time indicated on the solutions’

instruction label.

– Recover all the parts, rinse them abundantly, dry them perfectly and

proceed with the re-assembly in the distributor.

After re-positioning the container undertake to raise the flap in order to reset

the correct function (fig. 4.11).

For further safety after the assembly of the parts, effect some auto-

matic cleaning cycles so as to eliminate any eventual residues.

5.0 SOFTWARE INSTRUCTIONS

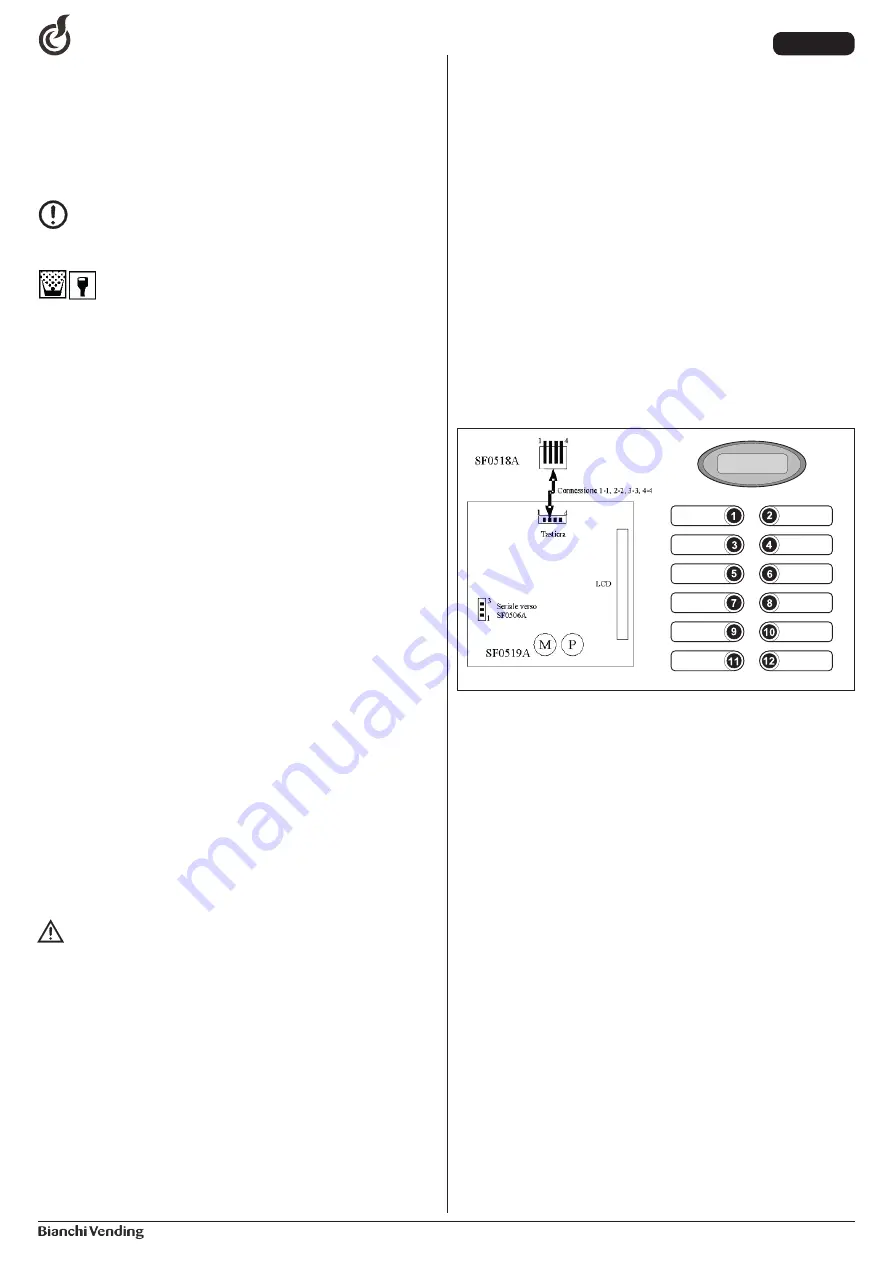

STANDARD MODE

PUSHBUTTON PANEL

The pushbuttons provided are meant for:

Key

1

: Selection 1

Key

2

: Selection 2

Key

3

: Selection 3

Key

4

: Selection 4

Key

5

: Selection 5

Key

6

: Selection 6

Key

7

: Selection 7

Key

8

: Selection 8

Key

9

: Selection 9

Key

10

: Selection 10

Key

11

: Selection 11

Key

12

: Selection 12

All the keys can also be used for the pre-selection functions.

On the SF0519A circuit board:

Key

P

: Programming

Key

M

: Maintenance

Please consult the description hereunder concerning the use of the DP1 and

DP2 pre-selection functions.

In the programming mode the keys have the following meaning:

Key 1

: Increase value

Key 2

: Escape

Key 3

: Decrease value

Key 5

: Move cursor

key 7

:

Enter

By programming either the DP1 or DP2 pre-selection function on one of the

P1 or P2 keys, then pressing on either the DP1 or DP2 pre-selection keys

followed by a second key, will activate selection options numbered 13 to 24

according to the following table:

Key number

LEI 200

DP1 + Key 1

DP1 + Key 2

DP1 + Key 3

Selection 13

DP1 + Key 4

Selection 14

DP1 + Key 5

Selection 15

DP1 + Key 6

Selection 16

DP1 + Key 7

Selection 17

DP1 + Key 8

Selection 18

DP1 + Key 9

DP1 + Key 10

DP1 + Key 11

DP1 + Key 12

DP2 + Key 1

DP2 + Key 2

DP2 + Key 3

Selection 19

DP2 + Key 4

Selection 20

DP2 + Key 5

Selection 21

DP2 + Key 6

Selection 22

DP2 + Key 7

Selection 23

DP2 + Key 8

Selection 24

DP2 + Key 9

DP2 + Key 10

DP2 + Key 11

DP2 + Key 12

Nota: sui tasti programmati come preselezioni non saranno ovviamente

disponibili le relative selezioni.

4.5.2 Payment system installation

The distributor does not have a payment system; any possible damages to

the distributor itself and/or objects and/or people deriving from its incorrect

installation are responsibility of who installs the payment system.

In-series arrangement for connection of the validator unit, 12-24 V.

For Executive/MdB kit payment systems.

The switches are to be directly connected to the keyboard card, the executive

serial systems require the payment system kit supplied separately.

Then go into programming for the correct settings.

Consult chapter ”5.0 SOFTWARE INSTRUCTIONS” so as to verify setting of

the parameters, that must be coherent with the system used.

4.5

Product container loading

(with machine off)

4.5.1 Loading containers

Filling is possible keeping the containers inserted, and by raising the upper

flap of the distributor (

Fig. 4.12

) or by extracting each container.

For granulated coffee in particular it is necessary to close the closure plat

before extracting the container.

(Fig.4.13)

.

– remove the covers of each container and load the product according to

the product indicated on the label

(Fig.4.14).

– pay attention that they there are no clots, avoid pressing the product

and using an excessive quantity, so as to avoid its aging in relation to the

consumption forseen in the time period between two loadings.

Check the container product capacity in the section TECHNICAL CHARACTE-

RISTICS.

4.5.3 Cup loading

Use only cups designed for automatic vending machines, with a diameter

of more than 70-74 mm, avoid compressing the cups between themselves

during the loading.

Loading must be carried out with machine off.

In installation phase with the cup dispenser completely empty, operate as

follows:

- Lift the bracket (Fig.4.15)

- Lift the cup column cover (Fig.4.16)

- Load the cups in the four tubes of the cup column (Fig.4.17)

- replace the cover and lower the bracket (Fig.4.18)

Summary of Contents for LEI200 E4S MC PD A/R AUTO

Page 55: ...55 3 1 3 3 4 1 4 4 4 5 4 2 4 3 3 2 50 Kg 2 18 4 6 4 7 4 8 ...

Page 56: ...56 4 9 4 10 4 11 4 12 4 13 4 14 6 1 4 16 4 17 4 18 4 19 4 20 4 21 4 15 ...

Page 58: ...58 6 15 6 16 7 2 7 1 7 3 7 4 7 5 7 6 7 8 7 7 7 9 6 14 ...

Page 66: ......

Page 71: ......

Page 72: ...Cod 11124111 Ed 05 2017 Rev 2 ...