CH – PE – WT100

B-

N

OTE TECNICHE PER L

’

INSTALLAZIONE

/I

NSTRUCTIONS FOR THE ISTALLER

N

OTAS TÉCNICAS PARA LA INSTALACIÒN

/

Edition 07–2003

– 22 –

I

UK

E

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

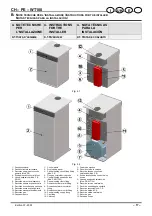

Vaso espansione sanitario

(opzionale)

Bulbo termostato bollitore

Bulbo termometro bollitore

Rubinetto riempimento circuito

riscaldamento

Presa pressione gas del

bruciatore

Valvola gas

Regolatore di pressione gas

Presa pressione ingresso valvola

gas

Elettrodo di rilevazione fiamma

(pilota intermittente)

Elettrodo di accensione (pilota

intermittente)

Bruciatore

Rubinetto di svuotamento circuito

riscaldamento

Corpo caldaia

Bulbo termostato riscaldamento

Bulbo termometro riscaldamento

Bulbo termostato di sicurezza

Bulbo termostato limitatore

bollitore

Manometro riscaldamento

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Central heating circuit filling up

cock

Gas pressure tap to burner

Gas valve

Gas pressure regulator

Gas valve inlet pressure tap

Flame detection electrode (pilota

intermittente)

Ignition electrode (pilota

intermittente)

Burner

Central heating circuit emptying

cock

Boiler body

Central heating thermostat bulb

Central heating thermostat bulb

Safety thermostat bulb

Storage heater limiting device

thermostat bulb

Central heating gauge

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Bulbo del termostato acumulador

Bulbo del termómetro

acumulador

Grifo de llenado circuito de

calefacción

Toma de presión de gas hacia el

quemador

Válvula de gas

Regulador de presión de gas

Toma de presión entrada válvula

de gas

Electrodo de detección de la

llama (pilota intermittente)

Electrodo de encendido (pilota

intermittente)

Quemador

Grifo de vaciado circuito de

calefacción

Cuerpo de la caldera

Bulbo del termostato para

calefacción

Bulbo del termostato para

calefacción

Bulbo del termostato de

seguridad

Bulbo del termostato limitador

acumulador

Manómetro calefacción

4.6 D

ATI TECNICI

“WT100”

4.6 “WT100”

T

ECHNICAL DATA

4.6 C

ARACTERÍSTICAS

TÉCNICAS

“WT100”

25 WT100

32 WT100

Portata termica nominale / Nominal thermal capacity / Capacidad calorífica nominal

kW

27,9

34,8

Portata termica minima / Minimum thermal capacity / Capacidad calorífica mínima

kW

18,6

28,5

Potenza utile massima / Maximum useful power / Potencia útil máxima

kW

25,0

31,5

Potenza utile minima / Minimum useful power / Potencia útil mínima

kW

16,0

25,0

R

ISCALDAMENTO

/ C

ENTRAL HEATING

/ C

ALEFACCIÓN

25 WT100

32 WT100

Temperatura massima / Maximum temperature / Temperatura máxima

°C

80

80

Temperatura minima / Minimum temperature / Temperatura mínima

°C

40

40

Pressione massima / Maximum pressure / Presión máxima

kPa

bar

300

3

300

3

Pressione minima / Minimum pressure / Presión mínima

kPa

bar

30

0,3

30

0,3

Perdita di carico del corpo caldaia / Boiler body loss of pressure

Pérdida de carga del cuerpo de la caldera

Pa

mbar

900

9

1300

13

S

ANITARIO

/ D

OMESTIC HOT WATER

/ A

GUA SANITARIA

25 WT100

32 WT100

Temperatura massima / Maximum temperature / Temperatura máxima

°C

65

65

Temperatura minima / Minimum temperature / Temperatura mínima

°C

35

35

Pressione massima / Maximum pressure / Presión máxima

kPa

bar

800

8

800

8

Capacità bollitore / Useful storage heater capacity / Capacidad útil acumulador

l

100

100

Portata sanitaria specifica / Specific domestic hot water flow

Caudal specífico agua sanitaria

(

∆

T = 30° K)

l/min

15

17

Prelievo continuo / Continuous drawing / Toma continua

(

∆

T = 25° K)

l/min

13

15

Prelievo continuo / Continuous drawing / Toma continua

(

∆

T =35° K)

l/min

9

11

Tempo massimo di ripristino bollitore / Maximum storage heater reheating time

Tiempo máximo de reposición acumulador

min

12

10

* Rif. norma EN 625 / Ref. EN 625 standard / Ref. norma EN 625

P

ORTATA GAS MASSIMA

/ M

AXIMUM GAS FLOW RATE

/ C

AUDAL MÁXIMO DE GAS

25 WT100

32 WT100

Metano G20 / Natural gas G20 / Natural G20

m

3

/h

2,95

3,70

Butano G30 / Butane G30 / Butano G30

kg/h

2,20

2,76

Propano G31 / Propane G31 / Propano G31

kg/h

2,18

2,73

P

ORTATA GAS MINIMA

/ M

INIMUM GAS FLOW RATE

/ C

AUDAL MÍNIMO DE GAS

Metano G20 / Natural gas G20 / Natural G20

m

3

/h

1,96

3,01

Butano G30 / Butane G30 / Butano G30

kg/h

1,46

2,24

Propano G31 / Propane G31 / Propano G31

kg/h

1,45

2,22

Summary of Contents for 25 CH

Page 2: ......