- 12 -

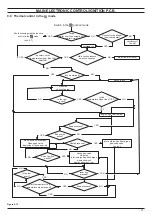

FAULT FINDING

FAUL

T FINDING

Components to check

Section of the manual

(note ref. in brackets)

– (1)

– (2)

– (3)

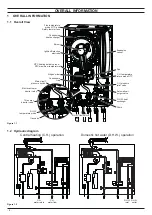

21.1

– (4)

5

6

7.2

8.2

14.3

9.5

10

11.4

12.2

14.5

15.2

16

17

18.4

19.2

19.2

20.1

– (7)

–

–

–

Appliance lock–out (*)

Defect

Power supply line

Gas supply line

Flue pipes

Cond. drain pipe and trap

C.H. circuit

D.H.W. circuit

Condensing heat exchanger

D.H.W. heat exchanger

Pump

Diverter valve

D.H.W. flow

switch

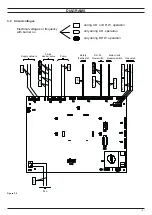

Fuses (Electronic p.c.b.)

Main electronic p.c.b.

Boiler settings

Control panel electr. p.c.b.

Gas valve

Main circuit pressure switch

D.H.W. filter

Main circuit temp. probe

D.H.W. temp. probe

By–pass valve

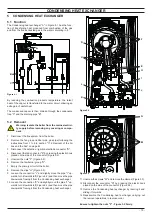

Fan / air restrictor

Ignition electrode / Detection

electrode

Safety thermostat

Gas restrictor

Flue temp. probe NTC

Expansion vessel

Safety valve

Pressure gauge

External temp. probe

No ”E” indication on display

The boile

r does not start either in C.H. or

D.H.W

. mode.

The control panel display OFF Fan still.

•

•

•

•

The

boile

r does not

supply D.H.W

. (cold wa

-

ter from the tap). Regular operation in C.H.

mode even during

a drawing of

f D.H.W

.

•

•

•

On C.H. mode the temperature of the main circuit reaches 90°C

and the

C.H.

system

does not heat. The boiler

operates correctly on D.H.W

.

mode.

•

•

•

Incorrect modulation.

•

•

•

•

Noisy bolier

.

•

•

•

•

•

•

Poor C.H. / D.H.W

. temperature (9).

•

•

•

•

•

Poor D.H.W

. temperature. Regular

opera

-

tion in C.H. mode.

•

•

•

(8)

•

Low

D.H.W

. flow

rate.

•

•

•

–

W

ater leaks from the safety valve during op

-

eration on C.H.

•

•

•

•

•

•

–

W

ater leaks from the safety valve

when the

boiler is of

f.

•

•

•

* Lock out is indicated as “

E

” on the display

.

Note

Useful information can be obtained also from the optical indication given by the appliance display (see section 4

.1)

.

1

Check for 230V~ between line (L) and neutral (N).

Verify the integrity of supply cable, plug and external fuses.

Check the polarity of line and neutral connection.

2

Check the gas supply pipe and isolation tap for gas tightness.

3

Check for soundness and absence of obstructions. V

erify

that

the

flue

terminal

is

correctly

installed

(see

clearances)

and ensure that exhaust gas is not sucked back by the boiler

.

4

Check

for

soundness

of

the

circuit

and

verify

its

correct

fillin

g

(see also installation manual).

5

A jammed by–pass could cause the over–heating of the main circuit and the intervention of the safety thermostat.

6

Using

the

flue

analyser

, check

the

CO

2

value

of

the

flue

gases.

This reading is a reference value for the gas valve setting.

7

Check the pressurization

of the expansion

vessel. Refer

to the installation manual for proper values.

8

D.H.W

.

pressure

too

high

or

flow

rate

too

high.

If

necessary

insert

a

flow

rate

limiter

(14.6).

9

The boiler do

esn’t reach the nominal heat input.

Summary of Contents for 47-583-46

Page 2: ......

Page 50: ...50 SHORT SPARE PARTS LIST 6 2 3 4 7 8 10 9 11 12 18 19 20 21 13 14 15 16 17 1 5 Figure 21 1...

Page 51: ......