- 46 -

FLUE TEMPERATURE PROBE NTC AND SAFETY THERMAL FUSE

19 FLUE TEMPERATURE PROBE NTC AND

SAFETY THERMAL FUSE

19 .1 Function

The Flue temperature probe NTC and Safety thermal fuse "A"

in Figure 19.1 and Figure 19.2 senses the temperature of the

combustion products that flow through the condensing heat ex

-

changer.

Figure 19 .1

A

If the temperature of the combustion products circuit reaches the

limit temperature, the Flue temperature probe NTC reduces the

gas flow rate to the burner. The temperature of the combustion

products should decrease to a safe value temperature.

In the case that the temperature of the combustion products

reaches a potentially dangerous value, the Safety thermal fuse

stops the boiler operation (lock-out).

This allows the use of plastic materials for the flue outlet pipes

and bends.

The use of kits different from the original isn’t however allowed,

since the flue pipes are integral parts of the boiler.

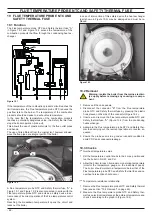

Figure 19 .2

A

B

A Flue temperature probe NTC and Safety thermal fuse "A" in

Figure 19.1 and Figure 19.2 is also connected in series with the

Flue temperature probe NTC and acts as a safety device in ex-

treme case of incorrect operation of the Flue temperature control

system.

Reaching the breakdown temperature it opens the circuit and

locks out the boiler.

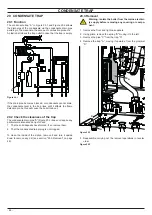

In case of intervention of this safety device the heat exchanger

(part shown in Figure 19.3) may be damaged and must be re-

placed.

Figure 19 .3

19 .2 Removal

Warning: isolate the boiler from the mains electrici-

ty supply before removing any covering or compo-

nent .

1 Remove all the case panels.

2 Disconnect the connector "B" from the Flue temperature

probe NTC and Safety thermal fuse by pressing the plastic

hook placed on the side of the connector (Figure 19.2).

3 Unscrew and remove the Flue temperature probe NTC and

Safety thermal fuse "A" (Figure 19.2) from the condensing

heat exchanger.

4 Assemble the Flue temperature probe NTC and Safety ther-

mal fuse carrying out the removal operations in reverse se-

quence.

5 Ensure the probe seal is in a good serviceable condition to

avoid POC and condensate leakage.

19 .3 Checks

Overheat temperature value

1 Set the temperature control knobs to their max. position and

run the boiler in D.H.W. and C.H.

2 Allow the boiler to reach its maximum operating temperature

(monitor the temperature gauge on the instrument panel).

The boiler should maintain a temperature below that of the

Flue temperature probe NTC and Safety thermal fuse and no

overheat intervention should occur.

Temperature-resistance relationship.

1 Remove the Flue temperature probe NTC and Safety thermal

fuse (see section "19.2 Removal" on page 46).

2 Measure the Flue temperature probe NTC and Safety ther-

mal fuse electrical resistance at the ambient temperature and

check it according to the graph in (Figure 19.4).

Summary of Contents for 47-583-46

Page 2: ......

Page 50: ...50 SHORT SPARE PARTS LIST 6 2 3 4 7 8 10 9 11 12 18 19 20 21 13 14 15 16 17 1 5 Figure 21 1...

Page 51: ......