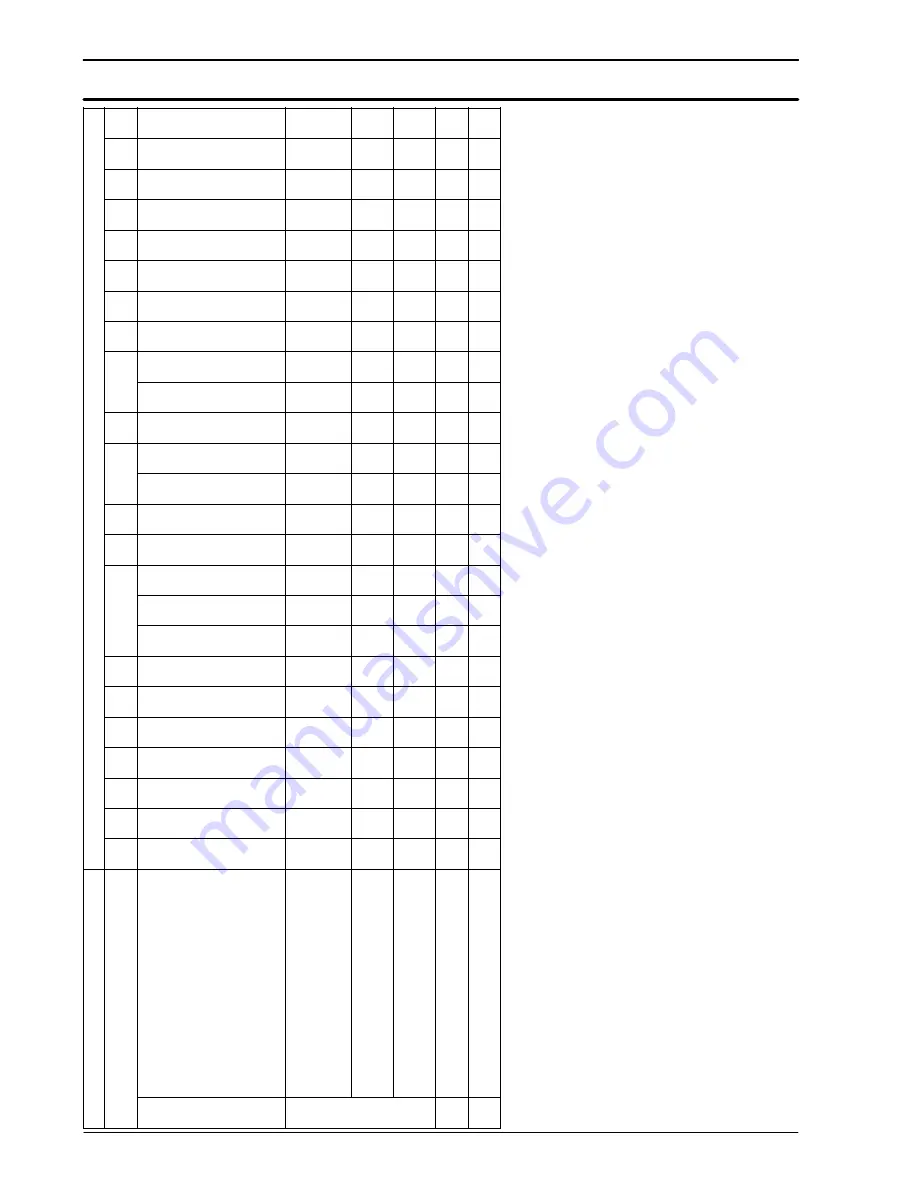

8

C

omp

on

en

ts

to

ch

ec

k

S

ec

tio

n

of

the

m

anual

!

(n

ot

e

ref

.i

n

brac

ket

s)

---

---

---

---

--- (7)

13.1

12.2

12.2

11.4

10

9.2

8.4

7

6.5

---

5

--- (4)

14.1

--- (3)

--- (2)

--- (1)

Appl

ianc

elock

- --ou

t(*

)

Roomth

emos

tat

del

ayed

Exte

rna

lte

mp.p

rob

e

Pres

sur

egauge

ext

ernal

Safe

tyv

alv

ee

xte

rna

l

Expans

ion

ves

sel

ext

ernal

Flue

temp

.p

rob

eN

TC

Gas

res

trictor

Safe

tyth

ermosta

t

Dete

ctione

lectr

ode

Ign

ition

elec

trod

e

Fan

/a

irr

estr

ictor

C.h

.ret

urn

tem

p.p

robe

C.h.

flo

wte

mp.

pro

be

Gas

val

ve

Con

trol

pan

elel

ectr.

p.c

.b.

Boil

erse

ttings

Mai

nel

ectron

ic

p.c

.b.

Fus

es

(E

lec

tro

nic

p.c.

b.)

Exte

rnal

pum

p

Conde

nsi

nghe

ate

xch

anger

C.h.

circ

uit

Cond.

dra

in

pipe

and

tra

p

Flue

pipe

s

Gas

suppl

yli

ne

Pow

ers

upply

lin

e

De

fe

ct

#

on

on

dis

pla

y

Th

e

boil

er

does

not

st

ar

t.

Th

e

con

trol

pa

ne

ld

is

pl

ay

O

FF

Fa

n

st

ill.

J

J

J

J

indi

catio

n

In

co

rrec

tm

od

ul

at

io

n

J

J

J

J

No”

Er”

i

N

oisy

bolie

r

J

J

J

J

J

J

J

---

W

ate

rl

ea

ks

from

th

e

sa

fe

ty

va

lv

e

du

rin

g

op

er

at

io

no

nc

/h

J

J

J

J

J

---

W

at

er

leaks

from

th

e

saf

et

y

val

ve

wh

en

th

e

bo

ile

ris

of

f.

J

J

J

*

Lock

ou

tis

in

di

ca

te

d

as

“

Er

”o

nt

he

di

sp

la

y.

No

te

U

se

fu

lin

fo

rm

at

io

n

ca

n

be

ob

ta

in

ed

al

so

fr

om

the

op

tic

al

in

dic

at

io

n

give

n

by

the

ap

pl

ia

nc

e

dis

pl

ay

(s

ee

se

ct

io

n

4.

1).

1

C

he

ck

fo

r230V~

between

lin

e

(L

)a

nd

ne

ut

ra

l(

N

)

Ve

rif

y

th

e

in

te

gr

ity

of

su

pp

ly

ca

bl

e,

pl

ug

an

d

ex

te

rn

al

fu

se

s.

C

he

ck

the

po

la

rit

y

of

line

and

ne

ut

ral

co

nne

ct

io

n

2

C

hec

k

th

e

gas

su

pp

ly

pi

pe

and

is

ol

at

io

n

tap

fo

rg

as

tig

ht

nes

s.

3

C

he

ck

fo

rs

oundne

ss

and

abs

en

ce

of

ob

st

ru

ct

io

ns

.V

er

ify

that

th

e

flu

e

te

rmin

al

is

co

rr

ect

ly

in

st

alle

d

(se

e

cle

ar

an

ce

s)

an

d

en

-

su

re

th

at

ex

haus

tg

as

is

no

ts

uc

ke

d

bac

k

by

the

bo

ile

r.

4

C

he

ck

fo

rs

oundne

ss

of

th

e

ci

rc

ui

tand

ve

rif

y

its

co

rr

ec

tfi

lli

ng

(s

ee

al

so

in

st

alla

tio

n

ma

nu

al)

.

5

A

ja

m

m

ed

by

---

pa

ss

co

ul

d

ca

us

e

th

e

ov

er

---

he

at

in

g

of

th

e

m

ai

n

ci

rc

ui

ta

nd

th

e

int

er

ve

nt

io

n

of

the

sa

fe

ty

th

er

m

os

tat

.

6

U

si

ng

th

e

flu

e

anal

yze

r,

ch

ec

k

the

C

O

2

val

ue

of

the

flue

gas

es

.

Thi

s

re

adi

ng

is

a

re

fe

re

nc

e

val

ue

fo

rt

he

gas

val

ve

se

tti

ng.

7

C

he

ck

th

e

pr

essu

riz

atio

n

of

th

e

ex

pa

nsio

n

ve

sse

l.

R

ef

er

to

th

e

in

st

al

la

tion

ma

nu

al

for

pr

op

er

va

lu

es

.

8

Th

e

bo

iler

do

es

n’

tr

eac

h

th

e

nom

in

al

he

at

in

pu

t.