Gas valve

23

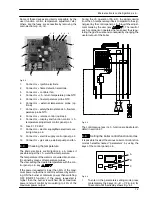

Fig. 8.9

22

Allow the analyser to give a stable reading.

23

Read the CO

2

% value.

It should be between:

Model

Type gas

CO

2

% value

(range)

Activ A 12OV

Activ A 15OV

Natural (G20)

8,9--- 9,8

ct

5O

Activ A 20OV

Activ A 25OV

Propane (G31)

9,9 --- 10,8

Tab. 8.2

To adjust the CO

2

% value rotate screw (1 --- Fig. 8.2)

(by rotating it clockwise the CO

2

% decreases).

24

Press keys A --- B --- C (Fig. 8.5) at the same time

again to exit the ”chimney sweep mode” and re-

turn to the previously set boiler status (Fig. 8.10)

C.h.

function

Fig. 8.10

25

Switch off the boiler and turn off the room ther-

mostat.

26

Close the air---flue sampling points.

27

After adjustment fit the protective brass plug (2,

Fig. 8.2).

Important: after the gas pressure checks and any

adjustment operations, all of the test points must be

sealed.

8.4

Checks

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

n

Check the on---off operators coils

1

Remove the front panel of the case.

2

Disconnect the electrical connector 4 (Fig. 8.2).

3

Measure the electrical resistance between the

connector pins of the on---off operators as illus-

trated in Fig. 8.11.

ON---OFF Operator

approx. 920

Ω

*

ON---OFF Operator

approx. 6 400

Ω

*

* at ambient temperature.

Fig. 8.11

8.5

Removal of the gas valve

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

1

Remove the front panel of the case as explained

in the section 2.3 of this manual.

2

Disconnect the connector

D

(Fig. 8.12).

3

Unscrew the screws

E

and disconnect the earth

connector

F

.

I

D

G

H

J

I

K

E

F

Fig. 8.12

4

Turn off the gas supply and disconnect the gas

isolation cock connector from the inlet port of the

gas valve.

5

Using pliers, remove the spring

G

and the rubber

pipe

H

(Fig. 8.12).

6

Unscrew the connectors

I

(Fig. 8.12) and remove

the pipe

J

.

7

Unscrew the screws

K

and remove the valve

(Fig. 8.12).

8

Reassemble the valve carrying out the removal

operations in reverse order.

Before fitting a new valve, it is advisable to pre--set

it as follows.

9

Remove the brass plug and turn the plastic screw

inside it fully clockwise until it stops. Do not over-

tight.

10

Turn it counter---clockwise 2 and 3/4 turns.