- 44 -

INST

ALLA

TION

- 44 -

INST

ALLA

TION

GENERAL REQUIREMENTS

facilitate complete filling of the system.

Expansion vessel

The appliance has an integral sealed expan

-

sion vessel to accommodate the increase of

water volume when the system is heated.

Refer to Fig. 4.5 on page 38 for its techni

-

cal data.

If the heating circuit has an unusually high wa

-

ter content, calculate the total expansion and

add an additional sealed expansion vessel

with adequate capacity.

Mains water feed: central heating

There must be no direct connection to the

mains water supply even through a non return

valve, without the approval of the Local Water

Authority.

Mains water feed: hot water supply

The domestic section of the boiler is designed

to withstand an internal domestic water pres

-

sure of 10 bar. Where it is likely that the mains

domestic water pressure may exceed 5 bar,

it is possible due to internal “water hammer”

effects that the pressure within the domestic

system can increase to a level in excess of

the 10 bar limit.

In these circumstances it is therefore recom

-

mended that a 3 bar pressure reducing valve

be fitted to the incoming mains water supply

and a mini expansion vessel installed on the

domestic circuit.

These devices will protect the boiler and the

domestic system from damage due to exces

-

sive domestic water pressure.

Filling

A method for initially filling the system and

replacing water lost during servicing must be

provided and it must comply with local water

authority regulations.

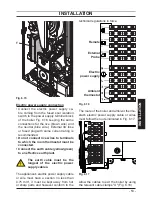

The correct method is shown in Fig. 5.5.

The temporary connection must be removed

immediately after filling.

Fig. 5.5

Temporary

connection

Control valve

Control valve

Double check valve

Supply pipe

(cold water inlet)

C.H. return pipe

The installer should ensure that no leaks ex

-

ist either inside the boiler or on the system as

frequent filling of the system could cause pre

-

mature scaling of the heat exchanger.

5.9

Domestic water

The domestic water installation must be in ac

-

cordance with the relevant recommendations

of BS 5546. Copper tubing to BS EN 1057 is

recommended for water carrying pipework

and must be use for pipework carrying potable

water.

For Ireland (IE), refer to I.S.813.2002.

5.10

Water treatment

C.H. circuit

Where a new boiler is fitted to a new system

with either plastic or copper pipes, it is impor

-

tant the system is fully flushed, on completion,

to ensure flux residues, swarf

, oils and other

installation debris is removed.

Where a new boiler is fitted to an existing sys

-

tem, it is important the debris from the existing

system is fully removed in order to ensure the

efficiency of the new appliance is maintained.

Details on flushing procedure are given in the

section "Initial filling of the system" on page

59 of this manual.

D.H.W. circuit (scale protection)

In areas where the water is ’hard’ (i.e. more

than 200 ppm total hardness as defined by BS

7593: 2006 Table 2) it is recommended that a

proprietary scale-reducing device is fitted into

Summary of Contents for ADVANCE 25C

Page 87: ......