- 57 -

INST

ALLA

TION

COMMISSIONING

7.6 Condensate pipe and traps

The full length of the condensate pipe

should be check for leaks.

Before running the boiler, ensure that the

built in condensate trap and any other trap

in the drain system is correctly filled with

water.

Fill the built in condensate trap

by removing the flue elbow and

pouring a cupful of water into

the flue outlet (Fig. 7.4).

Fig. 7.4

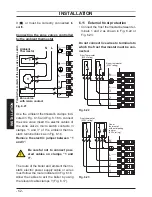

An alternative, to the removal of the flue el-

bow, pour the water through the flue sam-

pling point (Fig. 7.5).

Fig. 7.5

Sampling points

Flue exhaust

7.7 Checking the gas supply

pressure

This boiler has been factory tested to

the highest quality control standards

and set for the minimum and maximum

gas working pressures, connected to a

1 m flue and a gas supply pressure of

20 mbar.

Any variation in gas supply pressure or

flue length may result in the customer

experiencing a harmonic noise from the

boiler. In these circumstances, it may be

necessary to reset the burner gas pres-

sures in accordance with section 11 Gas

Valve of the Service Manual.

It should be noted that a Flue Gas Ana-

lyser is required for this procedure.

7.8 Checking the inlet pressure

• Remove the boiler body's front panel, see

section "Dismantling the external panels"

to page 74.

• When the boiler is switched off (out of or-

der), check the supply pressure by using

the 31 point in Fig. 7.6 and compare the

value read with that reported on the Gas

supply pressure table in the "Technical

Data" section (pag. 26 Advance Plus 25C,

pag. 29 Advance Plus 30C and pag. 32

Advance Plus 35C).

• Close well the pressure point 31 in Fig.

7.6.