Electronic control p.c.b.

19

A short pulse every 4 seconds

Boiler in stand---by condition.

(function control in

position).

Anti---freeze system active.

1 second ON 1 second OFF

Boiler ON condition

(function control in

or

position)

With the boiler switched ON (

or

) all the lamps

(7 in Fig. 29) are activated.

The following table gives the relationship between each

of the possible lamp combinations and their meaning.

Normally operating boiler

(see the previous table for details)

C.h. operation

D.h.w. operation

Frost protect operation

D.h.w. operation

Excessive temperature on primary circuit

Faulty c.h. temperature probe NTC

Faulty d.h.w temperature probe NTC

Faulty primary circuit

(no water or absence of flow)

Lack of burner ignition (no ignition signal from

the full seqence ignition device)

Ignition gas pressure adjustment

Minimum gas pressure adjustment

Lack of power supply or fauly electronic

control p.c.b. *

Fauly electronic control p.c.b. *

Lamp

OFF

Lamp

ON

Flashing lamp, alone

or simultaneously

with an other lamp.

Flashing lamp,

alternate with

another lamp.

* These conditions are normal only for a short time when the

power supply is applied to the boiler.

If permanent they indicate a faulty p.c.b.

10.5

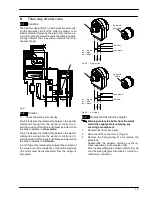

Dip---switch selectors

The function selectors 8 (Fig. 29 and Fig. 32) are micro-

switches with which it is possible to select the various

boiler control function modes.

In Fig. 32 the selectors are illustrated in the configur-

ation in which the boiler is set in the factory (natural gas

boiler).

ON (1)

OFF (0)

1 2 3 4

8

Gas conversion

Ignition gas pressure adjustment

Reignition frequency

Minimum gas pressure adjustment

Fig. 32

f

Selector 1

This forces the boiler to operate at the minimum gas

pressure in order to allow the adjustment of the mini-

mum gas pressure at the burner (on the modulation op-

erator of the gas valve).

After any adjustment operation the selector has to be

brought back to the normal position (ON).

f

Selector 2

This selects the boiler functions on the basis of the type

of gas used.

It allows the selection of the maximum supply current

given to the modulator device.

To set selector 2 correctly follow the table in Fig. 33.

Gas supply

Position of selector

Approx. Max current

through the modu-

lator device

Natural gas

On

120 mA

L.P.G.

Off

165 mA

Fig. 33

f

Selector 3

This forces the functioning of the boiler in order to allow

the optimal gas pressure at the burner to be adjusted

during the ignition phase.

The adjustment (see section 10.7) is done by means

of the potentiometer ”10” marked “ACC” (Fig. 29 on

page 17).

After the adjustment operations bring the selector back

to the normal position (ON).

gas pressure calibration

Normal

ON (1)

OFF (0)

Fig. 34

f

Selector 4

This allows you to select the minimum time that must

pass between two ignitions of the burner in c.h. func-

tion.

30 sec.

3 min.

ON (1)

OFF (0)

Fig. 35