- 26 -

GAS vALvE

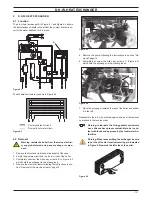

figure 11.4

11

7

8

9 10

15 Keep pressed the reset button 9 for about 10 seconds (Figure

11.4) until the lock-out signal lamp 10 blinks.

16 The lamps 11 should give the indication as in Figure 11.5.

figure 11.5

Where:

Lamp OFF

Lamp ON

17 Release and keep the reset button 9 pressed for more than

5 seconds until the lock-out signal lamp 10 is switched off.

The boiler will now go through an ignition sequence and the

burner will light.

18 Open at least one hot water tap fully.

Adjusting minimum gas valve setting

19 Set the knob 8 to the minimum position as illustrated in Figure

11.6.

figure 11.6

11

7

8

9 10

20 Allow the analyser to give a stable reading.

21 Read the CO

2

% value. It should be between 9,0 and 9,8 %

(natural gas G20) or between 10,0 and 11,0 % (LPG G31). To

adjust the CO

2

%value remove the brass plug by unscrewing

it and rotate the Allen key screw ø 4 mm (C - Figure 11.2) (by

rotating it clockwise the CO

2

% increases).

Checking the maximum gas valve setting

22 Set the knob 8 to the maximum position as illustrated in Fig-

ure 11.4.

23 Allow the analyser to give a stable reading.

24 Read the CO

2

% value. It should be between 9,0 and 9,8 %

(natural gas G20) or between 10,0 and 11,0 % (LPG G31).

To adjust the CO

2

% value rotate screw (B - Figure 11.2) (by

rotating it clockwise the CO

2

% decreases).

25 Switch off the boiler and turn off the hot water tap(s).

26 Close the air-flue sampling points.

27 After adjustment fit the protective brass plug (C - Figure 11.2).

Important: after the gas pressure checks and any adjust-

ment operations, all of the test points must be sealed.

11.4 Checks

Warning: isolate the boiler from the mains electrici-

ty supply before removing any covering or compo-

nent.

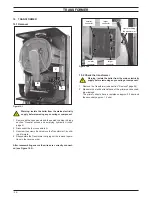

Check the on-off operators coils

1 Remove the front panel of the case.

2 Disconnect the electrical connector E (Figure 11.2).

3 Measure the electrical resistance between the connector pins

of the on-off operators as illustrated in Figure 11.7.

figure 11.7

Lower on-off operator

approx. 920 Ω*

Upper on-off operator

approx. 6400 Ω*

*at ambient temperature.

11.5 Removal of the gas valve

Warning: isolate the boiler from the mains electrici-

ty supply before removing any covering or compo-

nent.

1 Remove the front panel of the case as explained in the sec-

tion "Control panel" page 5, and the sealed chamber lid.

2 Remove the screw G and disconnect the connector H (Figure

11.8).

figure 11.8

G

H

I

J

k

3 Turn off the gas supply and disconnect the gas isolation cock

connector from the inlet port of the gas valve.

4 Using pliers, remove the spring I and the rubber pipe J (Fig-

ure 11.8).

5 Unscrew the connector K (Figure 11.8), remove the fixing fork

L and remove the pipe M (Figure 11.9).