Instructions for use

8

A

B

Fig. 2.15

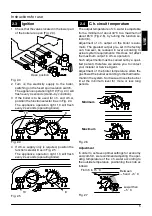

Activating the timed settings

Set the mode selector switch A to the

AUTO

posi-

tion shown in Fig. 2.16.

The current time appears in the display. The ON---

OFF display H indicates the current state of oper-

ation (according to the settings).

A

Fig. 2.16

Note: when the mode selector switch A is in the

AUTO

position and the boiler is switched off at the

fused spur isolation switch, the display H indicates

only the OFF state. The other indications are

blanked.

Reading the timed settings

Set the mode selector switch A to the

C1

position.

The symbols shown in Fig. 2.14 appears in the

display.

Press the “enter” button C. Each time the button

is pressed the display shows the details of the next

setting.

Changing or deleting the timed settings

Set the mode selector switch A to the

C1

position.

The symbols shown in Fig. 2.14 appears in the

display.

Press the “enter” button C until the display shows

the setting to be modified or deleted.

The time setting can be modified now by pressing

button D or E and the operation can be switched

on or off by pressing the button F.

To delete a time set press the button D or E until the

symbols shown in Fig. 2.14 appears in the time

display G.

The new settings are memorized by moving the

switch A to a different position.

Manual operation

The operation of the time switch can be forced on

or off constantly or for a timed period.

To force

constantly

on or off the timer operation

set the mode selector switch A to the

TIMER

posi-

tion. The symbols shown in Fig. 2.17 appears on

the display.

Fig. 2.17

The operation can be switched permanently on or

off by pressing the button F and leaving the switch

A in the

TIMER

position.

To force

a timed delay

on or off operation, set the

mode selector switch A in the

TIMER

position.

Set the time delay by pressing the button D or E

and the operation can be forced on or off by pres-

sing the button F.

The time delay can be set within the following

ranges:

1 to 23 hours with steps of 1 hour

1 to 27 days with steps of 1 day

The time delay setting is activated by moving the

switch A to the

AUTO

position.

The ON---OFF display H flashes indicating that the

current state of operation has been forced.

To delete the timed delay setting, set the mode se-

lector switch A in the

TIMER

position, press the

button D or E until the symbols shown in Fig. 2.17

appears in the display and then set the mode se-

lector switch A to the

AUTO

position

Setting example shown in Fig. 2.18:

forced ON state for 4 hours.

Fig. 2.18

Resetting

To completely reset the timer, press the reset but-

ton with a pointed object (pencil).

CAUTION: pushing the reset button will complete-

ly erase the settings as well as all the data, includ-

ing the current time.

USE