Commissioning

33

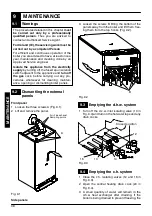

11 Cold flush the system to remove any loose par-

ticles and any system debris before starting the

boiler for the first time

The flushing procedure must be in line with

BS7593

Treatment of Water in d.h.w. c.h. Sys-

tems.

When the installation and second filling are

completed turn on the c.h. system and run it

until the temperature has reached the boiler

operating temperature. The system must then

be immediately flushed through.

This procedure must be repeated twice more.

During this operation we highly recommend

the use of a c.h. flushing detergent in the quan-

tities as specified by the appropriate manufac-

turer, whose function it is to dissolve any

foreign matter which may be in the system.

The above operation could save the invalida-

tion of your boilers guarantee and will also pre-

vent problems which you may experience in

the future if an inhibitory is not used.

7.5

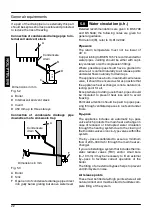

Condensate pipe and traps

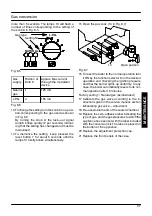

The full length of the condensate pipe should be

check for leaks.

The boiler has a built---in condensate trap pro-

vided with a ball valve that prevents the escape of

combustion products when the trap is empty.

It is however recommended that any other trap

in the drain system is correctly filled with water

before to run the boiler.

7.6

Lighting the boiler

Some products incorporate an anti cycling time

delay. It is normal when first switching the boiler on

for the boiler to operate on heating for a few sec-

onds then switch off. After 3---4 minutes has

elapsed the boiler will then re ignite and operate

perfectly normally. The ignition delay cycle does

not prevent normal operation of the boiler to pro-

vide d.h.w..

If external controls are fitted (e. g. Timeclock, room

thermostat) ensure they ”call for heat”.

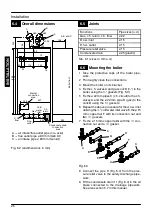

1 Turn on the electricity supply to the boiler,

switching on the fused spur isolation switch.

The appliance operation light 10 will flash

every 4 seconds.

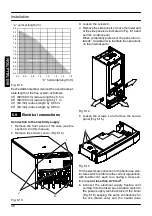

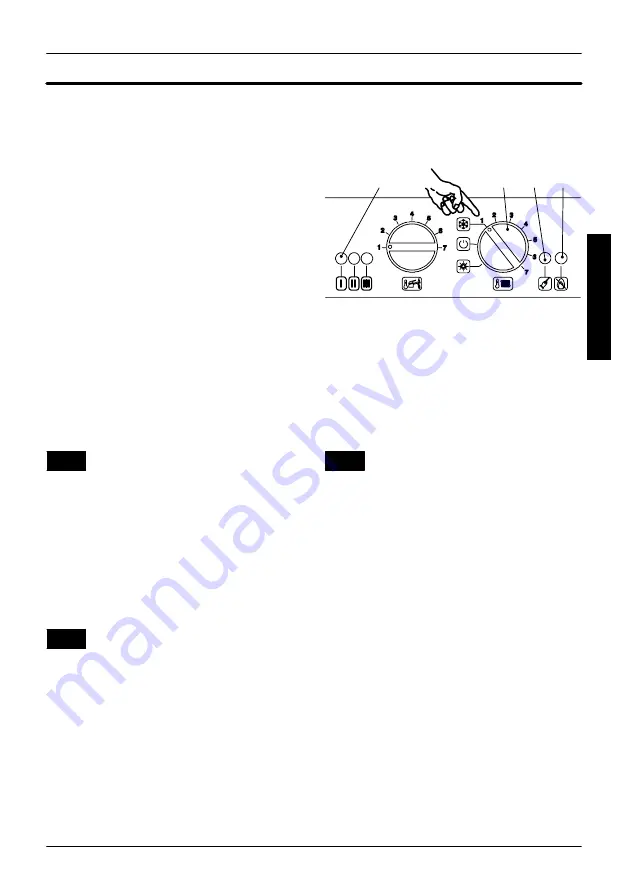

2 Turn the function selector 8 as in Fig. 7.3. The

appliance operation light 10 will flash every 2

seconds.

8

10

7

6

Fig. 7.3

The boiler will now go through an ignition se-

quence and the burner will light.

If during the ignition attempt period the boiler fails

to light, the full sequence control p.c.b. will go to

lockout and the lock---out signal lamp 6 will ap-

pear.

To reset the boiler press and release the boiler re-

set button 7.

7.7

Checking the gas pressure at

the burner

This boiler has been tested to the highest qual-

ity control standards.

The maximum and minimum gas pressures are

already set during this quality control process

however the checking procedure must be fol-

lowed to ensure maximum operating efficiency

from the boiler.

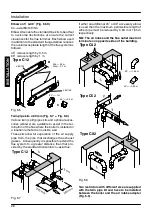

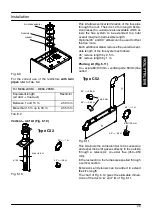

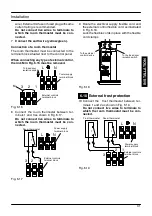

1 Remove the front panel of the case (see sec-

tion 9.2 in this manual) and the sealed

chamber lid.

2 Loosen the internal screw 33 (Fig. 7.4) on the

Outlet Pressure Test Point of the Gas Valve and

connect a pressure gauge using a suitable

hose.

3 Set the d.h.w. and c.h. temperature control

knobs to their maximum position. If external

controls are fitted (e. g. Timeclock, room ther-

mostat) ensure they ”call for heat”.

4 Switch on the boiler and open at least one hot

water tap fully.

IN

S

TA

LLA

TI

O

N