Installation

29

5.7 Electrical

connections

5.7

Электрические

подсоединения

1. Remove the front panel of the case

(see the section 8.2 in this manual).

1.

Снимите

переднюю

панель

корпуса

(

см

раздел

8.2

настоящего

руководства

).

2.

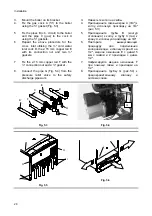

Remove the screws H and loosen the

screws I .(Fig. 5.5).

2.

Отверните

болты

Н

и

ослабьте

болты

I. (

Рис

.5.5)

3.

Move the lower part of the side panels

as indicated in Fig. 5.6 and pull the

control panel. When completely pulled

out, the panel can rotate 45°

downwards to facilitate the operations

on the internal parts.

3.

Сдвиньте

нижнюю

часть

боковой

панели

как

указано

на

рис

. 5.6

и

извлеките

панель

управления

.

После

того

,

как

Вы

ее

полностью

извлекли

,

панель

можно

повернуть

на

45

гр

.

по

направлению

вниз

,

чтобы

обеспечить

свободный

доступ

к

внутренним

частям

.

4.

Loosen the screws J and remove the

service panel (Fig. 5.7).

4.

Ослабьте

винты

J

и

снимите

сервисную

панель

(

рис

.5.7).

For the electrical connection to the boiler use

electric wires which conform to the current

regulations, with flexible cord, each core

having a cross section area not less than

0,75 mm

2

.

Для

электрического

подключения

котла

,

используйте

электропровода

которые

соответствуют

настоящим

нормам

,

в

гибкой

изоляции

,

с

сечением

не

менее

0,75

мм

2

для

каждой

жилы

.

J

Fig. 5.7

1

2

L

N

3

К

автомату

электропитания

Клеммная

колодка

электропитания

Клеммная

колодка

для

устройства

внешнего

контроля

K

Power supply

terminal block

External controls

terminal block

To the fused

spur isolation

switch

Fig. 5.8

5. Connect the electrical supply flexible

cord coming from the fused spur

isolation switch to the power supply

terminal block of the boiler ( Fig. 5.8)

keeping the same connections for the

live (brown wire) and the neutral (blue

wire). External 3 A fuse or fused plug

with same current rating is

recommended.

5.

Подключите

кабель

питания

,

идущий

от

автомата

к

блоку

питания

котла

(

Рис

. 5.8)

сохраняя

правильную

фазность

:

фаза

(

коричневый

провод

),

ноль

(

синий

провод

).

Рекомендуется

установка

внешнего

3

А

предохранителя

или

автомата

с

аналогичными

характеристиками

.

Do not connect live wires to

terminals to which the room

thermostat must be connected.

Не

подключайте

фазу

к

контактам

,

к

которым

будет

подключен

комнатный

термостат

.

6.

Connect the earth wire (yellow/green).

6.

Подключите

провод

заземления

(

желто

-

зеленый

)

Connection of a room thermostat

Подключение

комнатного

термостата