RIVA ADVANCE COMBI MANUAL

57

16. Gas Conversion Cont.

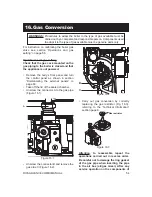

Figure 16.13

• To exit programming, position the function

selector 7 to “ “ (Figure 16.14), or

disconnect the electric power supply from

the boiler.

Figure 16.14

7

• Calibrate the gas valve according to

the instructions provided in the section

“Operations and gas setting” on page 56.

• Reposition the controls panel and remount

the front panel of the body.

• Apply the label indicating the gas

nature and pressure value for which the

appliance is regulated. The self adhesive

label is contained in the conversion kit.