General requirements

rev. 17.09.93

20

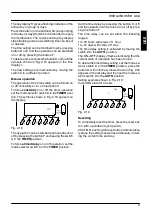

The minimum acceptable spacing from the ter-

minal to obstructions and ventilation openings are

specified in Fig. 5.1.

A

BC

E

F

G

I

JK

L

M

N

H

I

O

P

Q

D

Fig. 5.1

Terminal position

mm

A

Directly below a window or other opening

300

.

. . .

B

Below gutters, soil pipes or drain pipes

75

.

. . . . .

C

Below eaves

200

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

D

Below balconies*

600

.

. . . . . . . . . . . . . . . . . . . . . . . .

E

Below car port roof

NO

.

. . . . . . . . . . . . . . . . . . . . . . .

F

From vertical drain pipes and soil pipes

150

.

. . . .

G

From internal corners**

450

.

. . . . . . . . . . . . . . . . . .

H

From external corners

300

.

. . . . . . . . . . . . . . . . . . .

I

Above ground or balcony level

300

. .

. . . . . . . . . . . .

J

From a surface facing a terminal

600

.

. . . . . . . . . . .

K

From a terminal facing a terminal

1 200

.

. . . . . . . . .

L

From an opening in the car port

.

(e.g. door, window) into dwelling

NO

. . . . . . . . . . .

M Vertically from a terminal in the same wall

1 500

.

N

Horizontally from a terminal in the same wall 300

.

.

O Above the roof pitch with roof slope less

.

than or equal to 30

û

350

. . . . . . . . . . . . . . . . . . . . . .

Above the roof pitch with roof slope

more than 30

û

600

. . . . . . . . . . . . . . . . . . . . . . . . . . .

P

From wall face

600

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Q From, above or to side of an opening

300

.

. . . . . . .

*Wherever practicable to do so, the flue should be ex-

tended beyond the perimeter of the balcony

** Consideration should be given to adding protection

against condensate to the adjacent structure

5.4

Gas supply

The Gas meter is connected to the service pipe by

the local gas region or a local gas region contrac-

tor.

If the gas supply for the boiler serves other

appliances ensure that an adequate supply is

available both to the boiler and the other

appliance when they are in use at the same time.

Pipework must be of adequate size. Pipes of a

smaller size than the boiler inlet connection should

not be used.

Installation pipes should be fitted in accordance

with BS 6891 and the complete installation should

be tested for soundness.

For Ireland (IE), refer to I.S.813.2002.

5.5

Air supply

The room in which the boiler is installed does not

require a purpose provided air vent.

5.6

Ventilation

If installed in a cupboard or compartment, it is not

necessary to provide additional ventilation for

cooling for this particular product. However con-

sideration must be given to clearance require-

ments for maintenance (see section 6.2) and

under no circumstances must stored articles be al-

lowed to come into contact with the boiler or flue

pipe.

5.7

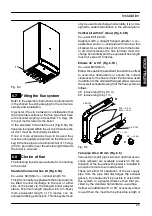

Condensate drain

Ensure that the condensate discharge complies

with the national or local regulations in force.

The condensate pipe must be fitted in accordance

with Building Regulations.

Drainpipe material should be resistant to acid as

the condensate is slightly acid with a pH less than

6.5.

The boiler includes a trap (32 on page 12) that pre-

vents the combustion products entering the drain,

however an additional trap with a seal of at least 75

mm and an air break between the traps is required

(Fig. 5.2).

The length of the condensate pipe should be kept

at minimum.

To avoid condensate being trapped:

---

the drainpipe should be run with a fall of at least

2.5

û

(45 mm/m) away from the boiler;

---

the number of bends and joints should be kept

at minimum;

INST

ALLA

TI

ON