General requirements

rev. 17.09.93

21

---

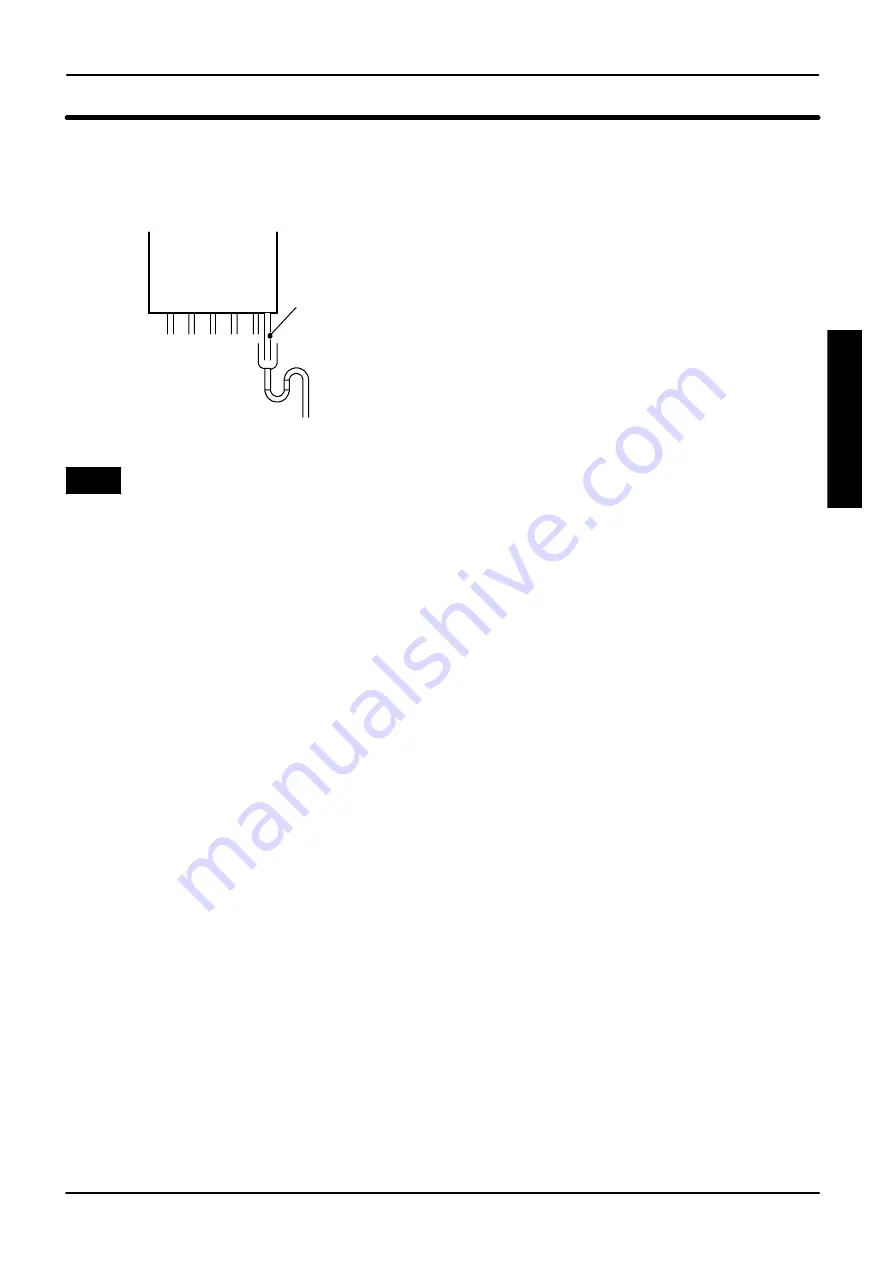

the drainpipe should be adequately fixed to

prevent pipe sagging.

If a part of the drainpipe runs externally this part

should be kept as short as possible and protected

to reduce the risk of freezing.

Condensate drain

Fig. 5.2

5.8

Water circulation (c.h.)

Detailed recommendations are given in BS 6798

and BS 5449; the following notes are given for

general guidance.

For Ireland (IE), refer to I.S.813.2002.

Pipework

The return temperature must not be lower of

30

û

C.

Copper tubing to BS EN 1057 is recommended for

water pipes. Jointing should be either with capil-

lary soldered or with compression fittings.

Where possible pipes should have a gradient to

ensure air is carried naturally to air release points

and water flows naturally to drain taps.

The appliance has a built---in automatic air release

valve, it should be ensured as far as possible that

the appliance heat exchanger is not a natural col-

lecting point for air.

Except where providing useful heat, pipes should

be insulated to prevent heat loss and to avoid

freezing.

Particular attention should be paid to pipes pas-

sing through ventilated spaces in roofs and under

floors.

By---pass

The appliance includes an automatic by---pass

valve which protects the main heat exchanger in

case of reduced or interrupted water circulation

through the heating system due to the closing of

thermostatic valves or cock---type valves within the

system.

The by---pass is calibrated to assure a minimum

flow of 500---600 lts/hr through the main heat ex-

changer.

If you are installing a system that includes thermo-

static radiator valves (TRV) and/or small bore

(8---10 mm) it may be necessary to fit an external

by---pass to facilitate correct operation of the

boiler.

The fitting of an external bypass helps to prevent

and limit system noise.

Air release points

These must be fitted at all high points where air will

natural collect and must be sited to facilitate com-

plete filling of the system.

Expansion vessel

The appliance has an integral sealed expansion

vessel to accommodate the increase of water vol-

ume when the system is heated.

Refer to Tab. 4.1 on page 18 for its technical data.

If the heating circuit has an unusually high water

content, calculate the total expansion and add an

additional sealed expansion vessel with adequate

capacity.

Mains water feed: central heating

There must be no direct connection to the mains

water supply even through a non return valve,

without the approval of the Local Water Authority.

Mains water feed: hot water supply

The domestic section of the boiler is designed to

withstand an internal domestic water pressure of

10 bar. Where it is likely that the mains domestic

water pressure may exceed 5 bar, it is possible

due to internal “water hammer” effects that the

pressure within the domestic system can increase

to a level in excess of the 10 bar limit.

In these circumstances it is therefore recom-

mended that a 3 bar pressure reducing valve be

fitted to the incoming mains water supply and a

mini expansion vessel installed on the domestic

circuit.

These devices will protect the boiler and the do-

mestic system from damage due to excessive do-

mestic water pressure.

Filling

A method for initially filling the system and replac-

ing water lost during servicing must be provided

INST

ALLA

TI

ON