Installation

24

total (wet) load. Refer to the weight given in the

technical data tables specific for each model.

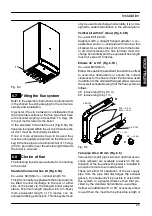

6.4

Overall dimensions

A --- air intake/flue outlet pipe (co---axial)

B --- flue outlet pipe ø 80 mm (twin kit)

C --- air intake pipe ø 80 mm (twin kit)

ø80

ø80

ø100

400

200

24

5

19

6

80

3

70

0

35

115

142

16

31

60

60

100

257

200

65

64

52

65

50

120

350

217

A, B and C

Boile

rf

ron

t

B

A

C

Gas

D.h.w.

C.h.

Cold

C.h.

return

flow

outlet

water

inlet

Electric

connection

area

Condensate

drain connection

area

120

ø80

C

Fig. 6.2 (all dimensions in mm)

6.5

Joints

Functions

Pipe sizes (o.d)

Gas, c.h. return, c.h. flow

ø 22

D.c.w. inlet

ø 15

D.h.w. outlet

ø 15

Pressure relief valve

ø 15

Condensate drain

ø 25 (plastic)

Tab. 6.1 (sizes in mm o.d.)

6.6

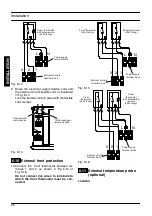

Mounting the boiler

1 Take the protective caps off the boiler pipe-

work.

2 Thoroughly clean the connections.

3 Mount the boiler on its bracket.

4 Fix the c.h. valves A and gas cock B (¾”) to the

boiler using the ¾” gaskets (Fig. 6.3)

5 Fix the ø 22 mm pipes C (c.h. circuit) to the c.h.

valves A and the ø 22 mm pipe D (gas) to the

cock B using the ¾” gaskets.

6 Repeat the above procedure for the d.c.w. inlet

utilising the ½” cold water inlet valve E, the ø 15

mm copper tail F with its connection nut and

two ½” gaskets.

7 Fix the ø 15 mm copper tail G with the ½” con-

nection nut and a ½” gasket.

C

A

A

B

D

C

E

F

G

Fig. 6.3

8 Connect the pipe H (Fig. 6.4) from the pres-

sure relief valve to the safety discharge pipe-

work.

9 Fit the condensate drain 11 (Fig. 6.4) in the air

brake connected to the drainage pipework.

See also section 5.7 in this manual.

INST

ALLA

TI

ON