4

2

Instructions for use

2.1

Warnings

Biasi UK Ltd support the Benchmark initiat-

ive. The Benchmark Log Book is located at

the back of this manual and should be com-

pleted by the Installing/Commissioning En-

gineer and handed over to the User for fu-

ture reference by other visiting Engineers.

Also included is the Service Interval Record

card that should be completed by the Ser-

vice Engineer following the annual service

maintenance of the boiler and system.

All CORGI Registered Installers carry a

CORGI ID card, and have a registration

number. Both should be recorded in your

Benchmark Log Book. You can check your

installer is registered by calling CORGI di-

rect on 01256 372300.

In order to guarantee safety and correct oper-

ation, it is essential that all the tests are carried

out by a competent and responsible service

engineer before lighting up the boiler.

The tests are described in the

installation in-

structions

in section 7

commissioning.

Ensure that the c.h. circuit is regularly filled with

water (even if the boiler is only used for d.h.w.

supply) checking that the pressure indicated

on the temperature and pressure gauge 4 is

not lower than that shown in Fig. 2.2.

If the pressure reading on the pressure gauge

is below that shown in Fig. 2.2, then the system

will require topping up. A filling loop is normally

provided by the installer for this purpose.

If you are in any doubt regarding this pro-

cedure you are advised to contact your In-

staller or an Approved Engineer.

This appliance is provided with a built in anti---

freeze system that operates the boiler when the

temperature is below 5

û

C

Therefore, when the boiler is not lit or used in

cold weather, with consequent risk of freezing

do not switch off the boiler at the fused spur

isolation switch or close the gas inlet cock

.

When you do not expect to use the boiler for a

long period and the boiler is not to be used for

frost protection then follow the instructions

given in section 2.6 on page 7.

2.2

Refilling procedure

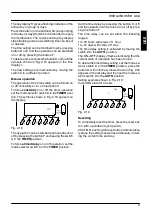

1 Isolate the boiler from the electrical supply at

the fused spur. Reconnect the filling loop as

demonstrated in Fig. 2.1.

Temporary

connection

Control valve

Control valve

Double check valve

Supply pipe

(cold water inlet)

C.h. return pipe

Fig. 2.1

2 Open the valves of the filling loop and watch

the gauge until it reaches normal filling pres-

sure as shown in Fig. 2.2.

4

Normal filling

pressure

Fig. 2.2

3 Close the valves and remove the filling loop.

If you experience any difficulty with the oper-

ation of the boiler, switch off the boiler immedi-

ately at the fused spur isolation switch and

contact your Installer or an approved Service

Engineer

Air introduced into the boiler during this filling pro-

cess will vent through the automatic air purger

fitted to the boiler. You may also find it necessary

to vent air from your radiator circuit using your

radiator key, however be aware that excessive

venting will cause the pressure in the system to

drop.

Always ensure that the pressure gauge is set at the

required pressure.

2.3

Ignition

1 Check that the valves located in the lower part

of the boiler are open (Fig. 2.3).

USE