18

6

Installation

6.1

Warnings

The use of gas appliances is subject to

statutory control; it is essential to observe

the current regulations and laws in force

(see also chapter 5).

The appliance must discharge combustion

products directly outside or into a suitable ex-

haust duct designed for this purpose.

Combustion products must be discharged

using original flue kits only, since they are inte-

gral parts of the boiler.

For Propane, the appliance must also conform

with the requirements of the distributors and

comply with current Regulations and laws in

force.

The safety relief valve and the condensate

drain must be connected to a suitable drain, or

discharge in a safe manner.

The electrical wiring must conform with current

Regulations, in particular:

---

the boiler

must

be earthed using the cor-

rect bonding clamp.

---

a fused spur isolation switch, with a gap of

at least 3 mm between the contacts must be

installed near to the boiler. Refer to section

6.9 in this chapter for the electrical connec-

tions.

In no circumstances will the manufacturer

be held responsible if the warnings and in-

structions contained in this manual have

not been complied with.

6.2

Precautions for installation

For the installation proceed as follows:

---

The boiler must be fixed to a strong wall.

---

The dimensions for the exhaust fume duct de-

tailed in section 6.7 and the correct procedures

for installing the duct, depicted in the instruc-

tion leaflet included with the flue kit, must be

complied with during installation.

---

To allow maintenance procedures it is necess-

ary to leave the minimum gaps indicated in

Fig. 6.1.

25

25

250

200

Fig. 6.1 (all dimensions in mm)

---

When installing the boiler in a cupboard, cover

or alcove allow at least 50mm permanent clear-

ance from the front face of the boiler. Also en-

sure sufficient clearance to allow free access

for servicing and the lowering of the front con-

trol panel.

---

If the boiler is installed outside, cover the ap-

pliance to protect it against the elements and

add some special anti---freeze (neutralised) to

the c.h. system.

---

Before installing the boiler on an existing c.h.

system, flush it out thoroughly before fitting the

boiler, so as to remove muddy deposits.

---

It is advisable to equip the system with a sedi-

ment filter, or use a water---treatment product in

the circulating water.

The latter option in particular, not only cleans

out the system, but also has an anti---corrosive

effect by promoting formation of a protective

skin on metal surfaces and neutralising gases

present in the water.

We recommend the use of a suitable universal

inhibitory to protect the c.h. system from cor-

rosion.

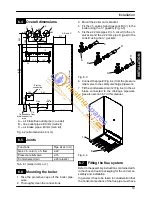

6.3

Installing the bracket

Precautions

Before mounting the bracket, check that the di-

mensions for fitting the exhaust fume duct are

complied with (refer to the leaflet included with the

flue kit, packed separately).

Utilise the paper template supplied with the boiler

to determine the fixing position for the bracket and

boiler. Securely mount the bracket to the wall

using appropriate fixings suitable for the type of

wall construction and capable of supporting the

total (wet) load. Refer to the weight given in the

technical data tables specific for each model.

IN

S

TA

LLA

TI

O

N