Installation

22

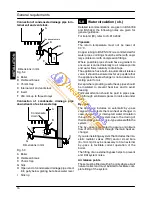

1 Remove the front panel of the case (see the

section 9.2 in this manual).

F

G

G

H

Fig. 6.9

2 Remove the screws F and G (Fig. 6.9).

3 Loosen the screws

H.

Fig. 6.10

4 Remove the side panels or move the lower part

of the side panels as indicated in Fig. 6.10 and

pull the control panel.

When completely pulled out, the panel can ro-

tate 45

˚

downwards to facilitate the operations

on the internal parts.

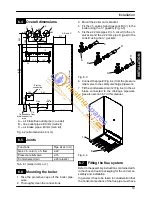

5 Loosen the screws I and remove the service

panel (Fig. 6.11).

I

Fig. 6.11

For the electrical connection to the boiler use elec-

tric wires which conform to the current regulations,

with flexible cord, each core having a cross sec-

tion area

not less than 0,75 mm

2

.

6 Connect the electrical supply flexible cord

coming from the fused spur isolation switch to

the power supply terminal block of the boiler

(Fig. 6.12) keeping the same connections for

the live (brown wire) and the neutral (blue

wire). External 3 A fuse or fused plug with same

current rating is recommended.

Do not connect live wires to terminals to

which the room thermostat must be con-

nected.

7

Connect the earth wire (yellow/green).

Connection of a room thermostat

The room thermostat must be connected to the

terminal block situated next to the control panel.

Any external controls and connection lines

must be rated at 230 V but under no circum-

stances should external live voltage be con-

nected to the room thermostat link on the

boiler.

Do not connect live wires to terminals to which

the room thermostat must be connected.

When connecting any type of external control,

the link J in Fig. 6.12 must be removed.

IN

S

TA

LLA

TI

O

N