General requirements

rev 17 09 93

19

Expansion vessel

The appliance has an integral sealed expansion

vessel to accommodate the increase of water vol-

ume when the system is heated.

Refer to Tab. 4.1 on page 11 for its technical data.

If the heating circuit has an unusually high water

content, calculate the total expansion and add an

additional sealed expansion vessel with adequate

capacity.

Mains water feed: central heating

There must be no direct connection to the mains

water supply even through a non return valve,

without the approval of the Local Water Authority.

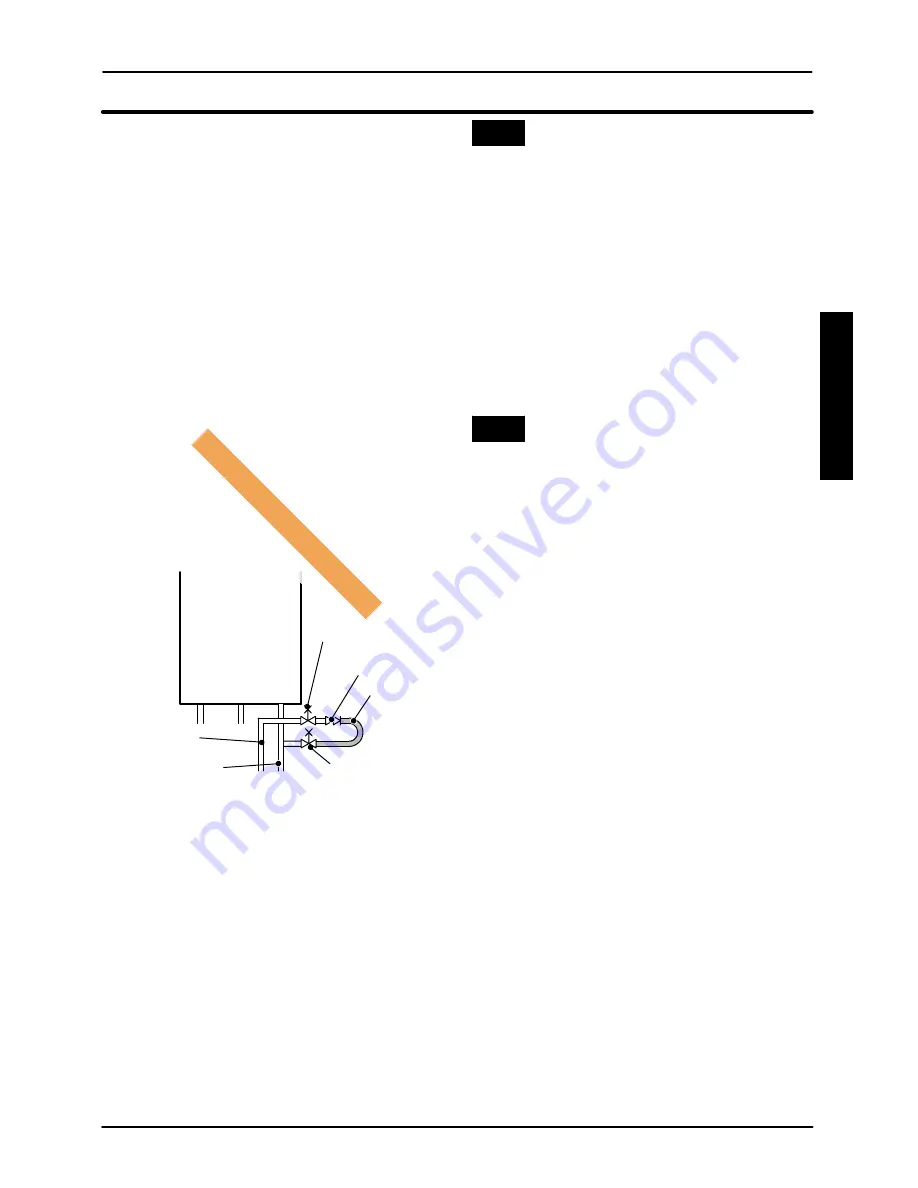

Filling

A method for initially filling the system and replac-

ing water lost during servicing must be provided

and it must comply with local water authority regu-

lations.

The correct method is shown in Fig. 5.4.

The temporary connection must be removed

immediately after filling.

Temporary

connection

Control valve

Control valve

Double check valve

Supply pipe

(cold water inlet)

C.h. return pipe

Fig. 5.4

The installer should ensure that no leaks exist

either inside the boiler or on the system as fre-

quent filling of the system could cause premature

scaling of the heat exchanger.

5.9

Water treatment

Central heating circuit

Where a new boiler is fitted to a new system with

either plastic or copper pipes, it is important the

system is fully flushed, on completion, to ensure

flux residues, swarfs, oils and other installation de-

bris is removed.

Where a new boiler is fitted to an existing system,

it is important the debris from the existing system

is fully removed in order to ensure the efficiency of

the new appliance is maintained.

Details on flushing procedure are given in the sec-

tion 7.3 of this manual.

5.10

Electrical supply

Warning, this appliance must be earthed.

External wiring to the appliance must be carried

out by a competent person and be in accordance

with the current I.E.E. Regulations and any local

regulations which apply.

Reference should be made to the current ETCI

rules for electrical installations.

For Ireland (IE), refer to I.S.813.2002.

The boiler is supplied for connection to a 230 V~

50 Hz supply. The supply must be fused at 3A.

The method of connection to the electricity supply

must facilitate complete electrical isolation of the

appliance by the use of a fused spur isolation

switch. Its installation permits a complete switch-

ing off in the conditions of the overvoltage cat-

egory III. Alternatively it can be used a 3A fused

three pin plug and unswitched shuttered socket

outlet both complying with BS 1363.

The point of connection to the electricity supply

must be readily accessible and adjacent to the

appliance except were the appliance is installed in

a bathroom this must then be sited outside the

bathroom.

IN

S

TA

LLA

TI

O

N