8

GAS CONVERSION

34

8.1

Warnings

The commissioning of this boiler and sys-

tem must only be undertaken by a pro-

fessionally qualified person in accordance

with the requirements of the Gas Safety In-

stallation and Use Regulations and be ap-

proved by C.O.R.G.I.

Components used to adapt it to the type of gas

available must be genuine parts only.

8.2

Procedures

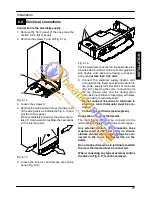

1 Check that the gas cock (12 in Fig. 8.1) fitted

under the boiler is turned off and the appliance

is switched off at the mains isolating spur.

Closed position

12

Fig. 8.1

2 Remove the front panel of the case (see the

section

General access and emptying hydraulic

circuits

in the service manual).

3 Take off the lid of the sealed chamber.

4 Take the front panel of the combustion

chamber off and remove the burner (33 on

page 9). See section

Ignition and detection

electrodes

in the service manual for detailed in-

structions.

5 Carry out the conversion for the type of gas, re-

placing the burner injectors correctly.

6 Re---assemble the burner, the front panel of the

combustion chamber.

7 Switch on the appliance at the mains isolating

spur.

8 Turn the boiler OFF positioning the function se-

lector 7 as indicated in Fig. 8.2.

7

9

6 5

8

Fig. 8.2

9 Disconnect the electrical connectors of the

C.h. temperature probe NTC 20 in Fig. 8.3

20

Fig. 8.3

10 Keep pressed the reset button 6 for about 10

seconds until the lock---out signal lamp 5

blinks.

11 Connect the the elctrical connectors of the C.h.

temperature probe NTC 20 in Fig. 8.3

12 Press the reset button 6 repeatedly (4 times)

until the lamps 9 give the indication as in

Fig. 8.4 (gas type mode).

Where:

Lamp OFF

Lamp ON

Fig. 8.4

At this step it is possible to visualize the current set-

ting by keeping the reset button 6 pressed for

more than 5 seconds. The lamps 9 will flash a

M

A

IN

TE

NA

NCE