- 34 -

INST

A

ll

ATI

o

N

- 34 -

INST

A

ll

ATI

o

N

GENERAl REQUIREMENTS

• the number of bends and joints should be

kept at minimum.

The drain pipe should be adequately fixed

to prevent pipe sagging.

If a part of the drainpipe runs externally this

part should be kept as short as possible and

protected to reduce the risk of freezing.

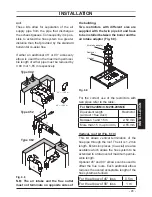

Fig. 5.2

Connection of condensate drainage pipe to

internal soil and vent stack.

Dimensions in mm

45

0

A

Condensate

drain

b

C

D

A

Boiler

b

Internal soil and vent stack

C

Invert

D

450 mm up to three storeys

Fig. 5.3

Dimensions in mm

Connection of condensate drainage pipe

downstream of a sink waste trap

A

Condensate

drain

E

F

A

Boiler

E

Sink

F

Open end of condensate drainage pipe

direct into gully below grating but above

water level

5.8 Water circulation (c.h.)

Detailed recommendations are given in BS

6798, BSEN 12828: 2003, BSEN 12831:

2003 & BSEN 14446: 2004; the following

notes are given for general guidance.

For Ireland (IE), refer to I.S.813.2002.

Pipework

The return temperature must not be lower of

40°C. Copper tubing to BSEN 1057 is rec-

ommended for water pipes. Jointing should

be either with capillary soldered or with

compression fittings.

Where possible pipes should have a gradi-

ent to ensure air is carried naturally to air

release points and water flows naturally to

drain taps.

The appliance has a built-in automatic air

release valve, it should be ensured as far as

possible that the appliance heat exchanger

is not a natural collecting point for air.

Except where providing useful heat, pipes

should be insulated to prevent heat loss and

to avoid freezing.

Particular attention should be paid to pipes

passing through ventilated spaces in roofs

and under floors.

by-pass

The appliance includes an automatic by-

pass valve which protects the main heat

exchanger in case of reduced or interrupted

water circulation through the heating system

due to the closing of thermostatic valves or

cock-type valves within the system.

Summary of Contents for Riva Plus HE M296.24SC

Page 56: ...56 NOTES...

Page 57: ...57 NOTES...