- 30 -

Fan and air pressure sensor

14 fan and air pressure sensOr

14 .1 function

The function of the Fan A (Figure 14.1 and Figure 14.2) is to

force the products of combustion through the condensing heat

exchanger to the outside air via the flue system.

The Fan is supplied by the full sequence ignition device at the

beginning of the ignition cycle.

Its correct functioning is controlled by means of an Air pressure

sensor B (Figure 14.1 and Figure 14.2) .

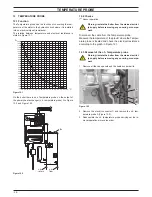

figure 14 .1

a

b

14 .2 checks

Check of the fan

warning: isolate the boiler from the mains electrici-

ty supply before removing any covering or compo-

nent .

1 Remove all the case panels and the sealed chamber lid.

2 Disconnect the connectors C (Figure 14.2) and measure the

electrical resistance of the motor that has to be about:

43 Ω - M296.24SR/C

25 Ω - M296.28SR/C

(at ambient temperature).

figure 14 .2

a

c

b

Check of the Air pressure sensor operation

this test must be carried out with the sealed chamber

closed .

1 Remove the caps of the pressure test points located on the

top of the boiler and connect a differential pressure gauge

(Figure 14.3).

2 Switch on the boiler.

figure 14 .3

3 Run the boiler at minimum by disconnecting the gas valve

modulation operator.

4 Compare the value on the gauge with the following:

75 Pa (0,75 mbar) - M296.24SR/C

92 Pa (0,92 mbar) - M296.28SR/C

5 Run the boiler at maximum (connect the modulation opera-

tor).

6 Compare the value on the gauge with the following:

125 Pa (1,25 mbar) - M296.24SR/C

155 Pa (1,55 mbar) - M296.28SR/C

7 With values less than:

64 Pa (0,64 mbar) - M296.24SR/C

82 Pa (0,82 mbar) - M296.28SR/C

The ignition is not allowed and appropriate fault indication is

given (see section "Operation lights" page 17).