Remarque : les appareils dont la plaque indique 230 V peuvent fonctionner sur 220 V, et ceux dont la

plaque indique 120 V peuvent fonctionner sur 110 V. Dans les deux cas cependant, la capacité de

chauffage diminuera d’environ 8 %. La plaque d’identification se trouve à l’arrière de l’appareil.

3. Raccordez le câble d’alimentation à la prise située à l’arrière de l’appareil.

4. Placez l’appareil sur un plan de travail ou surface plane, ou le cas échéant, dans une hotte d’aspiration,

en s’assurant que les trous d’aération situés sous l’appareil ne soient pas obstrués.

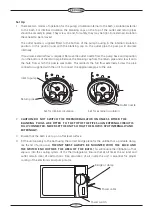

5. Les symboles ci-dessous situés à côté des témoins lumineux sur la face avant de l’appareil ont la

signification suivante :

: témoin d’alimentation

: témoin de chauffage

: témoin d’excès de température

6. Les symboles situés sur ou à côté de l’interrupteur de l’appareil ont la signification suivante :

O

: arrêt

l

: marche

Après UTIlIsATIOn

Lorsque vous avez fini de chauffer les échantillons, n’oubliez pas que certaines parties de l’appareil - les

éprouvettes, leurs supports et autres accessoires - risquent d’être très chaudes. Il est donc recommandé

de toujours prendre les précautions citées plus haut.

gArAnTIE

L’appareil est garanti contre tout défaut ou visde fabrication pour la durée figurant sur la carte de

garantie, à compter de la date d’achat de l’appareil. Au cours de cette période, toutes les pièces

défectueuses seront remplacées gratuitement, dans la mesure où la défaillance n’est pas due à une

mauvaise utilisation, un accident ou une négligence. Toute réparation sous garantie sera effectuée par le

fournisseur.

Malgré la description et les spécifications de l’appareil données dans le manuel de l’utilisateur, Techne se

réserve le droit d’effectuer les changements nécessaires à l’appareil ou à tout élément qui entre dans sa

composition.

Ce manuel a été exclusivement rédigé à l’attention des clients de Techne, et aucun élément de ce guide

d’instructions ne peut être utilisé comme garantie, condition ou représentation concernant la description,

commercialisation, adaptation aux conditions d’utilisation ou autre des appareils ou leurs composants.

7

Summary of Contents for Techne TE-10A

Page 39: ...NOTES 39 ...