Bierkühl Oy

+358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland

www.boscleantec.com

Operation and maintenance manual

BOS® Cleantec ventilation duct inspection

SIVU 12

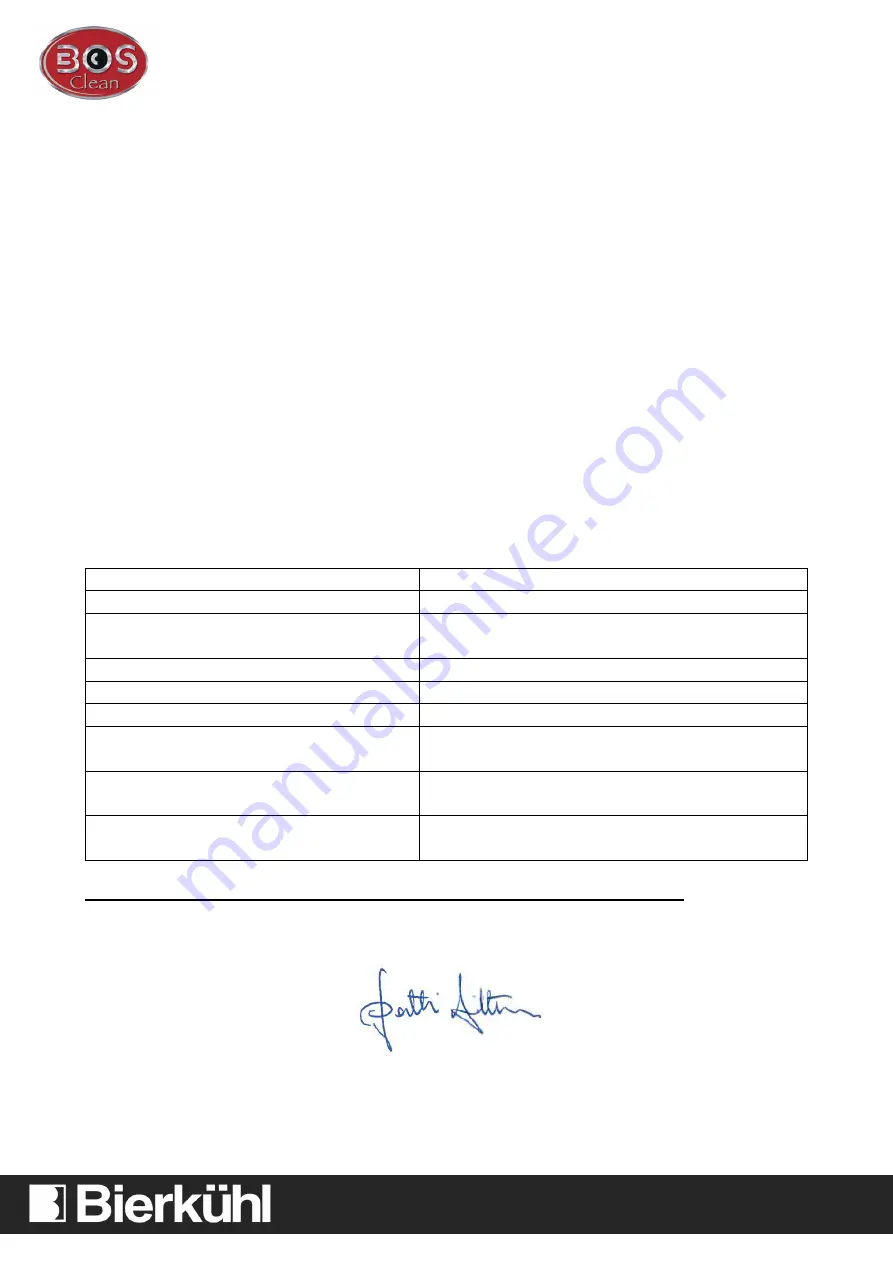

DECLARATION OF CONFORMITY

Manufacturer:

Bierkühl Oy, Pellonlaita 1 50600 MIKKELI FINLAND

Tel.:

+358 440 178 111

Website:

www.boscleantec.com

Product designation: Electric duct cleaning machine

Product name:

BOS® Clean

Intended use:

Duct description, inspection and recording

Serial number:

Year of manufacture::

We hereby declare that the product named above has been designed to comply with the Finnish

Government Decree on the safety of machinery (400/2008) and meets the requirements of the

Machinery Directive( 2006/42/EY). We also declare that the following Directives and

harmonised standards have been applied:

Essential characteristics and performance

Harmonised technical specification

Safety of machinery

SFS – EN ISO 12100:2010

Electrical equipment of machinery – Part 1:

General requirements

SFS _ EN 60204-1:2007

Decree on the safety of machinery

Finnish Government Decree No. 400/2008

Machine Directive (MD )

MD 2006 / 42 / EY

Low Voltage Directive (LVD)

2014/35/EU

Electromagnetic Compatibility (EMC)

Directive

EMC 2004/108/EY

2014/30/EU

Restriction of Hazardous Substances

(RoHS) Directive

2011/65/EU

Waste Electrical and Electronic Equipment

Directive (WEEE)

WEEE 2012/19/EU

This product conforms with the requirements to achieve CE marking.

Bierkühl Oy 26.04.2021

Pentti Hiltunen

Managing Director