14

July 2020

Installation, Operation and Maintenance Manual

MAN616_EAC Rev. 5

Section 2: Installation

Installation

7.

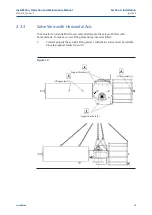

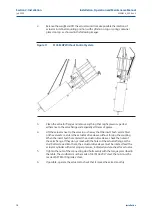

Connect a sling to the support points of the actuator and lift it: make sure the

sling is suitable for the actuator weight. When possible, it is easier to assemble the

actuator to the valve if the valve stem is in the vertical position. In this case the

actuator must be lifted while keeping the flange in the horizontal position.

8.

Clean the actuator flange and remove anything that might prevent a perfect

adherence to the valve flange and especially all traces of grease.

9.

Lower the actuator onto the valve in such a way that the insert bush, assembled

on the valve stem, enters the actuator drive sleeve. This coupling must take place

without forcing and only with the weight of the actuator. When the insert bush has

entered the actuator drive sleeve, check the holes of the valve flange. If they do not

meet with the holes of the actuator flange or the stud bolts screwed into them,

the actuator drive sleeve must be rotated; feed the actuator cylinder with air at

proper pressure, indicated on data-sheet for actuator.

10.

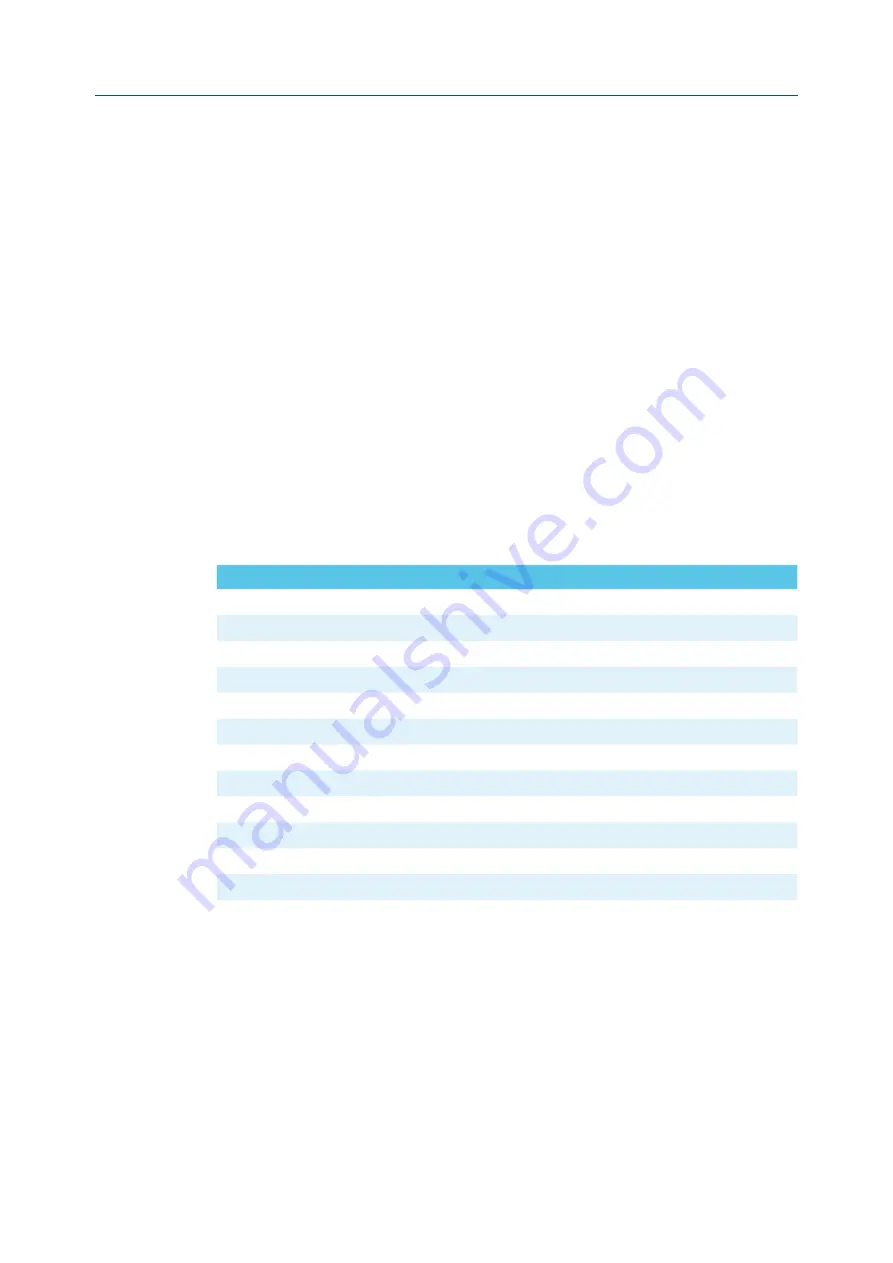

Tighten the nuts of the connecting stud bolts evenly with the torque prescribed in

the table. The stud bolts must be made of ASTM A320 L7 steel; the nuts must be

made of ASTM A194 grade 2 steel.

11.

If possible, operate the actuator to check that it moves the valve smoothly.

Thread size

Recommended tightening Torque (Nm)

M8

20

M10

40

M12

70

M14

110

M16

160

M20

320

M22

420

M24

550

M27

800

M30

1100

M33

1400

M36

1700

Table 6.

Torque Table