26

006

46

41

008

46

41

009

46

41

0100

46

41

0150

46

41

0200

17

60

0350

17

60

0400

17

60

0700

17

60

1100

17

80

1200

17

80

2000

17

80

2500

17

100

3800

17

100

5100

17

100

5400

17

100

8300

17

100

9600

17

100

9800

17

100

11000

17

100

15000

17

130

15600

17

130

July 2020

Installation, Operation and Maintenance Manual

MAN616_EAC Rev. 5

Section 3: Operation and Use

Operation and Use

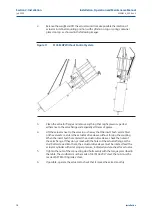

1.

Loosen the lock nut “d”.

2.

If the actuator angular stroke is stopped before reaching the end position,

unscrew the stop screw “v” by turning it anticlockwise until the valve reaches the

correct position.

3.

If the stop-screw is too hard to be operated, reduce or remove the cylinder

pressure, in order to move the mechanism far from the screw. Operate the

setting-screw and then pressurize again the cylinder to reach end position.

4.

If the actuator angular stroke is stopped beyond the end position, screw the stop

screw by turning it clockwise until the valve reaches the correct position.

5.

Tighten the lock nut, after having correctly placed the threaded seal washer

“s” and “w”.

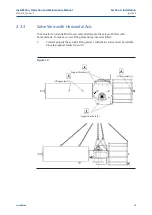

To operate the adjustments refer to following table:

Spring container size

Wrench C1 (mm)

Wrench C2 (mm)

Table 9.