3

Installation, Operation and Maintenance Manual

MAN616_EAC Rev. 5

July 2020

Section 1: General Warnings

General Warnings

1.3

Description of the Actuator

“ALGAS-QA” quick acting spring-return pneumatic low pressure actuators, are suitable for

the operation of quarter turn valves (ball valves, butterfly valves, plug valves).

These actuators are suitable to achieve a very short time in emergency operation performed

by the spring, independently from the flow capacity of supply lines to the actuator.

In fact the quick operation is requires normally only to bring the valve to the “safe” position.

The operating time can be lower than one second, depending on the process

characteristics, valve size and operating pressure.

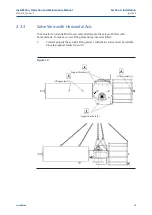

The actuator is made up of a weatherproof scotch yoke mechanism transforming the linear

movement of the pneumatic cylinder (or mechanical manual override, if foreseen) and of

the spring into the rotary movement, which is necessary for operation.

The pneumatic cylinder is fitted with an integral “quick exhaust valve” directly assembled on

the end flange.

Furthermore the cylinder has a specific dumping system to gradually reduce the speed in

the last portion of the valve stroke, avoiding possible impact damages to the valve trim and

to the actuator itself.

The spring-return pack incorporates up to four springs, fully encapsulated in a factory

welded cartridge: this ensures safety to personnel and simplifies assembly. The spring

action can be easily changed in the field from to close in to open or from to open in to close

(modular design).

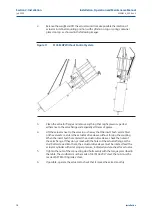

The angular stroke of the yoke is adjustable between 82° and 98° by means of the external

mechanical stops screwed into the end flange of the pneumatic cylinder and into the end

flange of the spring-return pack . The cover of the scotch yoke mechanism is arranged for

the assembly of the required accessories (position-transmitter, signaling-limit switches,

positioner, etc.) by means of proper matching units. The above mentioned accessories are

operated by the actuator drive sleeve.

The housing of the scotch yoke mechanism has a flange with threaded holes to fix

the actuator to the valve either directly or, if required, with the interposition of an adaptor

flange or a mounting bracket.

The actuator yoke has a hole with keyways suitable for the assembly of an insert bush or a

stem extension. Their internal hole is machined (by BIFFI or at Customer's care), according

to the shape and dimensions of the valve stem.

BIFFI can supply different types of control system following Customer's requirements.