Installation, Operation and Maintenance Manual

September 2019

MAN720_IMVS2000v2_IOM Rev. 6

Section 10: Installation – Start-Up

Installation – Start-Up

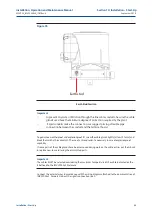

Figure 35

Earth stud

Earth Stud Position

Important:

•

to prevent any water infiltration through the line cable conduits, be sure the cable

glands used have the minimum degree of protection required by the plant.

•

if rigid conduits make the connection, we suggest placing a flexible pipe

connection between the conduit and the terminal board.

To guarantee weatherproof and explosionproof fit, screw the cable glands tightly (at least 5 turns) and

block them with a thread sealant. The use of a thread sealant is necessary in case of explosionproof

capability.

If some parts of the cable glands have been removed during work on the cable entries put them back

into place now to avoid losing the dismantled parts.

Important:

The cables MUST be selected considering the maximum Temperature of the cable indicated on the

label fixed to the IMVS2000v2 Enclosure.

Connect the external wires in accordance with the wiring diagram attached to the documentation of

IMVS2000v2. For details about the signals connection see 9.

93

Summary of Contents for IMVS2000v2

Page 2: ......