5

Isis

®

WWW.BIGASSFANS.COM ©2011 DELTA T CORP. DBA BIG ASS FAN CO. ALL RIGHTS RESERVED

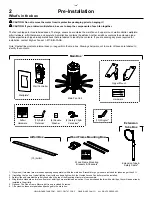

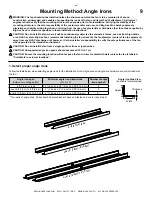

Important weights

Part

Weight

Upper mount

1.24 lbs (0.56 kg)

Lower mount

1.5 lbs (0.68 kg)

Extension tube (1-ft)

1.21 lbs (0.55 kg)*

Mounting bracket kit

2.54 lbs (1.15 kg)

Tools needed

Big Ass Fans recommends gathering the following tools prior to beginning installation.

Note: This list of suggested tools is not

exhaustive. Additional tools may be necessary.

Mechanical installation

Standard wrench set

Standard socket and ratchet set

Torque wrench capable of 25 ft·lb (33.9 N·m)

Phillips and flat head screwdrivers

Standard allen wrench set

Drill

Hacksaw

Level

Tape measure

Electrical installation

Phillips and flat head screwdrivers

#10 to #14AWG strippers

Medium size channel locks

Multimeter

*Add 3.5 lbs (1.58 kg) for every additional foot of extension tube.

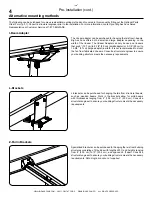

Pre-Installation (cont.)

Summary of Contents for Isis

Page 1: ...INSTALLATION GUIDE For help call 1 877 BIG FANS or visit www BigAssFans com ...

Page 16: ...Notes ...

Page 44: ......

Page 46: ......

Page 52: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ...REV H 2425 Merchant Street Lexington KY 40511 1 877 BIG FANS 1001250101 1001250101 ...