6.8

Proximity Sensors Continued

6.0

Adjustments

Other than adjusting the sensor so it makes a good signal

connection to the trigger target, 4 sensors can be adjusted

to increase speed and efficiency of the Transtacker. Also

these are adjustments are used to help damage happening

to the Transtacker.

6.8.1

Turntable - Middle

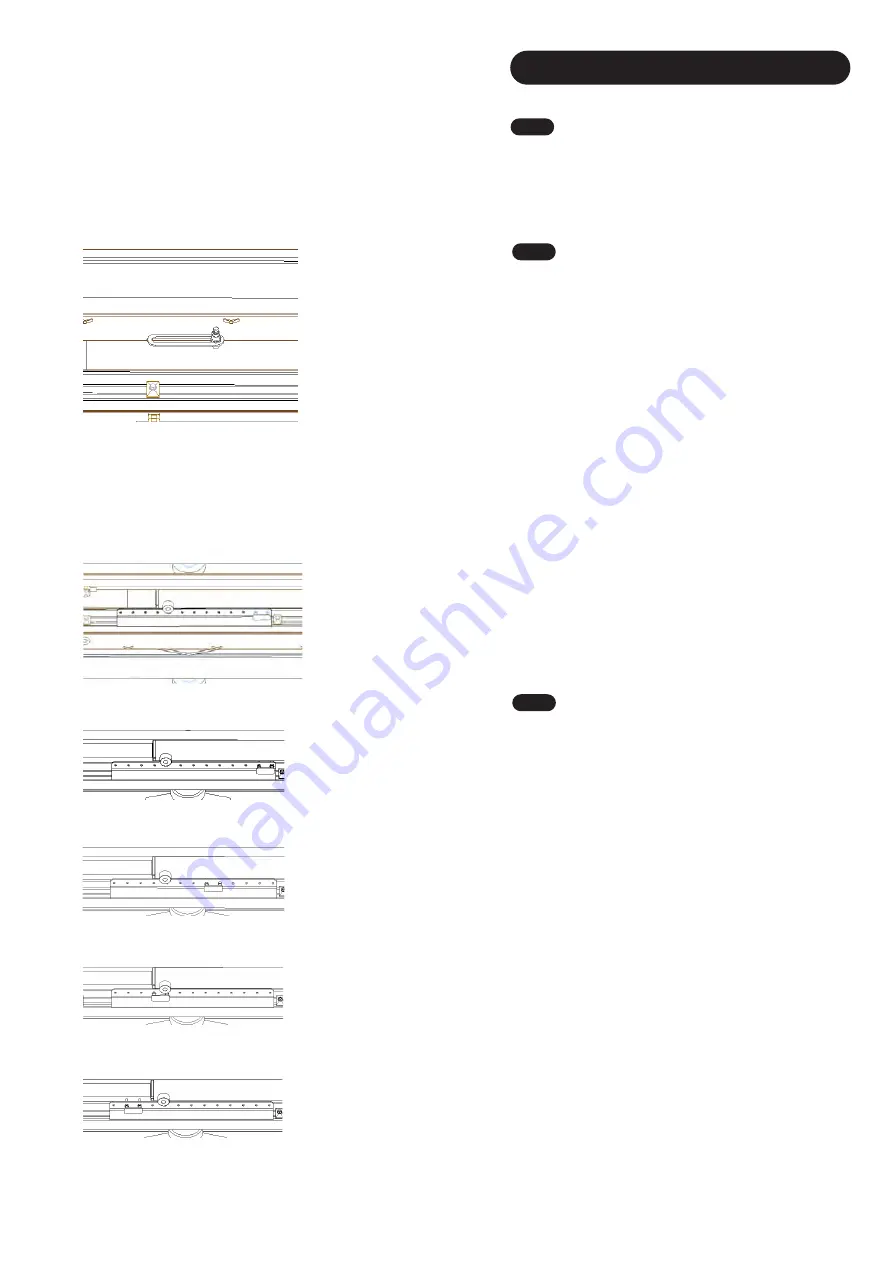

The Turntable - Middle sensor is located within a large

slot

ted

bracket

underneath the platform in the middle

(

Fig.

10

3

).

This is to fine adjust when the turntable comes to

rotate, this is most important on your final layer as the

bales sometimes stick out further to the front.

In this case, if you find the turntable gets stuck in rotation

about half way around, this is because the bales on the

turntable are tight up against the bales on the platform the

this sensor needs adjusting.

To bring the turntable away from the bales on the platform,

slide the sensor towards the front of the Transtacker.

To speed up the turntable rotate cycle you want to have the

turntable traveling the least distance as possible, so slide

the sensor towards the back of the Transtacker. However if

the turntable get stuck as mentioned above, you will need

to slide it forwards again.

Note

: Make sure small adjustments are made at a time to

increase accuracy of adjustments

. Check before adjusting

again.

Note:

This sensor should be factory set. Do not adjust

unless you are a skill

ed

operator and have a great

understanding of the machine.

Fig.

10

3

6.8.2

Turntable - Extend

Th

e Turntable -

Extend

sensor is located with

a large

selection of holds of the inside of the 'Pipe Carrier' in the

middle of the platform.

(

Fig. 10

4

).

This is to fine adjust

how far the turntable extends when its in its full extend

motion. The adjustment of this sensor is important

because it depends on what size bales you are working

with.

When working with 700

mm

high bales, use the closest

holes to the front of the Transtacker, holes 1 & 2 (

Fig.

10

5

).

For 900mm high bales, use holes 5 & 6 from the front of

the Transtacker

(

Fig. 10

6

).

For 1200mm high bales, use holes 9 & 10 from the front

of the Transtacker

(

Fi

g. 10

7

)

.

For 1300mm high bales, use holes 11 & 12 from the front

of the Transtacker

(

Fig.

10

8

).

Note:

This is only a guide. For finer adjustment use other

holes around suggested adjustment.

Note

: Big Bale Co South Ltd does NOT take

responsibility for incorrectly adjusted sensors. Contact

Big Bale Co South Ltd for more in depth detail for

adjustments.

Fig.

10

4

Fig.

10

5

Fig.

10

6

Fig. 10

7

Fig. 10

8

28

Summary of Contents for Transtacker 4100

Page 61: ...58...

Page 62: ...59...

Page 63: ...11 0 Hydraulic Systems 11 4 Valve Block Schematic Fig 168 60...

Page 67: ...13 0 Maintenance 13 2 Pickup Grease Points Fig 172 64...

Page 68: ...13 0 Maintenance 13 3 Grab Arm Grease Points Fig 173 65...

Page 69: ...13 0 Maintenance 13 4 Turntable A Frame Grease Points Fig 174 66...

Page 70: ...13 0 Maintenance 13 5 Side Gate Grease Points Fig 175 67...

Page 71: ...13 0 Maintenance 13 6 Rear Clamps Grease Points Fig 176 68...

Page 72: ...13 0 Maintenance 13 7 Chassis Grease Points Fig 177 69...

Page 73: ...13 0 Maintenance 13 8 Platform Grease Points Fig 178 70...

Page 74: ...13 0 Maintenance 13 9 Axle Grease Points Fig 179 71...

Page 84: ...16 0 Operators Notes 81...

Page 85: ...82...

Page 86: ...83...

Page 87: ...84...