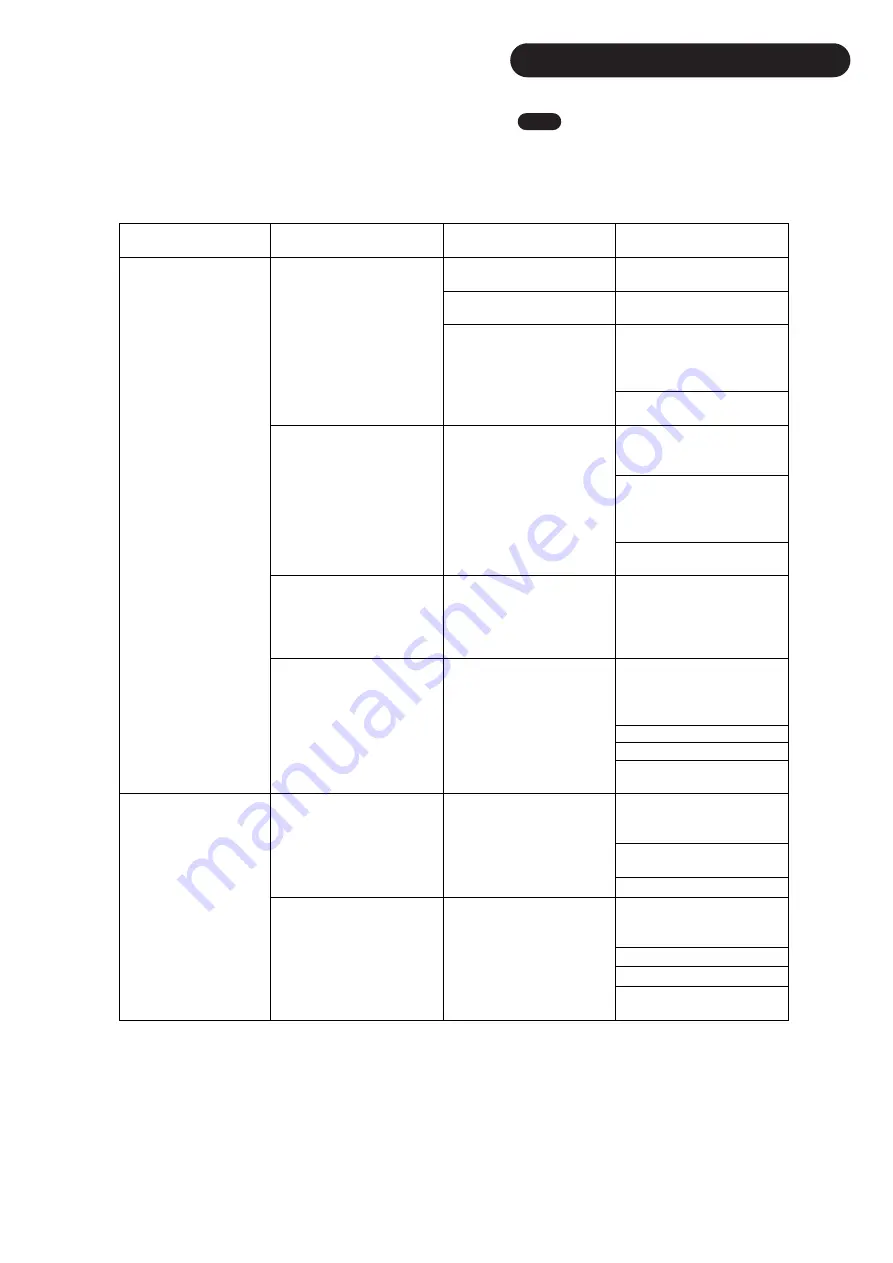

Not pressurised all the way

up

Forks Pressure Sensor has

hit its desired pressure

Increase the trigger

pressure

Side Gates Open

(Works

in line with below

function)

Not opening at all

Fork pressure trigger has

not been satisfied

Decrease Fork trigger

pressure

No power to selector valve

solenoid

Check for power supply to

solenoid, wiring loom fault

Side Gate left and right

proximity sensor

The sensor may be

damaged and giving false

reading. Check sensor LED

at back

If sensor is ok, check wiring

loom for fault

Side Gates Open too far

Side Gate left and right

proximity sensor

The sensor may be

damaged and not reading

the trigger

Make sure the sensor is

close enough to its trigger.

Or it will pass without

triggering (

Section

6.8

)

If sensor is not damaged,

check wiring loom for fault

Side Gates Open unevenly

Wiring to selector valve

solenoid wrong way around

If the side gate wiring loom

is on the opposite side to

what it should be, it will

create a problem with the

proximity sensors

Side Gate opens but doesn’t

complete cycle

Side Gate left and right

proximity sensor

Adjust Side Gate left and

right proximity sensor so

that it is triggered (

Section

6.8

)

Wiring fault

Proximity sensor fault

Check Grab Arm open

proximity sensor

Grab Arm Open

(Works

in line with above

function)

Grab Arm not opening at all

Fork pressure trigger has

not been satisfied

Decrease Fork trigger

pressure if pressure can’t be

achieved

Faulty pressure transducer –

change pressure transducer

CAN Bus wiring problem

Grab Arm opens but doesn’t

complete cycle

Grab Arm open proximity

sensor

Adjust Grab Arm proximity

sensor so that it is triggered

(

Section

6.8

)

Wiring fault

Proximity sensor fault

Check Side Gate left and

right proximity sensor

8

.0

Trouble

s

hooting

8

.

8

Auto Open Troubleshooting

Continue

d.

Fig. 1

4

7

41

Summary of Contents for Transtacker 4100

Page 61: ...58...

Page 62: ...59...

Page 63: ...11 0 Hydraulic Systems 11 4 Valve Block Schematic Fig 168 60...

Page 67: ...13 0 Maintenance 13 2 Pickup Grease Points Fig 172 64...

Page 68: ...13 0 Maintenance 13 3 Grab Arm Grease Points Fig 173 65...

Page 69: ...13 0 Maintenance 13 4 Turntable A Frame Grease Points Fig 174 66...

Page 70: ...13 0 Maintenance 13 5 Side Gate Grease Points Fig 175 67...

Page 71: ...13 0 Maintenance 13 6 Rear Clamps Grease Points Fig 176 68...

Page 72: ...13 0 Maintenance 13 7 Chassis Grease Points Fig 177 69...

Page 73: ...13 0 Maintenance 13 8 Platform Grease Points Fig 178 70...

Page 74: ...13 0 Maintenance 13 9 Axle Grease Points Fig 179 71...

Page 84: ...16 0 Operators Notes 81...

Page 85: ...82...

Page 86: ...83...

Page 87: ...84...