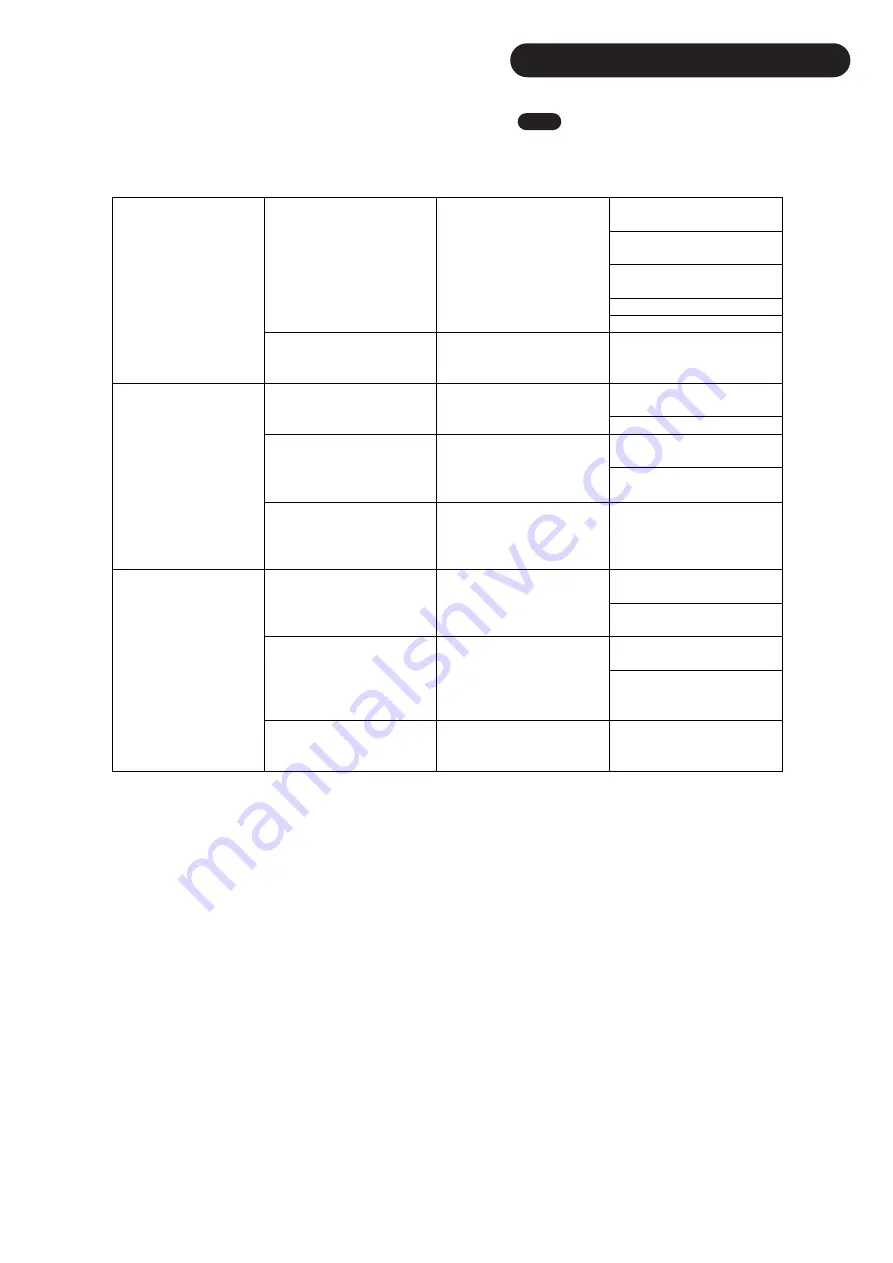

Pickup height not correctly

set for bale size

Trigger point needs

adjusting

Rotary

Sensor requires

Calibration (

Section

6.9

).

Faulty Sensor

Faulty wiring

Tines Don’t Fully Retract

Tines Retract pressure

sensor has hit its desired

pressure

Increase Tines Retract

Trigger Pressure

Hooks Insert

(Works in

line with below

function)

Hooks Don’t Insert

Power To Solenoid

Check for power supply to

solenoid, wiring loom fault

Solenoid could be faulty

Hook’s Don’t Fully Insert

Hooks Insert pressure

sensor has hit its desired

pressure

Increase Hook insert trigger

pressure

Fault with Pressure

Transducer

Once inserted, the hooks

start to drop out (down)

The Hook valve in the

selector valve

The valve is stuck opening

allowing for the pressure in

the Hook ram to drop. New

valve is needed

Pickup Lower

(Works in

line with above

function)

Pickup Doesn’t Fully Lower

Pickup Rotary Sensor Angle

False Trigger

Pickup Sensor requires

Calibration (

Section

6.9

)

Trigger Pickup Lower needs

altering

Pickup Doesn’t Lower at All

Tine Retract pressure sensor

has not hit its desired

pressure

Trigger pressure set too

high. Lower trigger pressure

Faulty Pressure Transducer

– change pressure

transducer

Pickup won’t complete its

cycle

Pickup Rotary sensor angle

Pickup lower angle has not

been achieved. Re-calibrate

sensor (

Section

6.9

)

8

.0

Trouble

s

hooting

8

.

9

Auto Pickup Troubleshooting

Continued.

Fig. 1

4

8

43

Summary of Contents for Transtacker 4100

Page 61: ...58...

Page 62: ...59...

Page 63: ...11 0 Hydraulic Systems 11 4 Valve Block Schematic Fig 168 60...

Page 67: ...13 0 Maintenance 13 2 Pickup Grease Points Fig 172 64...

Page 68: ...13 0 Maintenance 13 3 Grab Arm Grease Points Fig 173 65...

Page 69: ...13 0 Maintenance 13 4 Turntable A Frame Grease Points Fig 174 66...

Page 70: ...13 0 Maintenance 13 5 Side Gate Grease Points Fig 175 67...

Page 71: ...13 0 Maintenance 13 6 Rear Clamps Grease Points Fig 176 68...

Page 72: ...13 0 Maintenance 13 7 Chassis Grease Points Fig 177 69...

Page 73: ...13 0 Maintenance 13 8 Platform Grease Points Fig 178 70...

Page 74: ...13 0 Maintenance 13 9 Axle Grease Points Fig 179 71...

Page 84: ...16 0 Operators Notes 81...

Page 85: ...82...

Page 86: ...83...

Page 87: ...84...