7

4

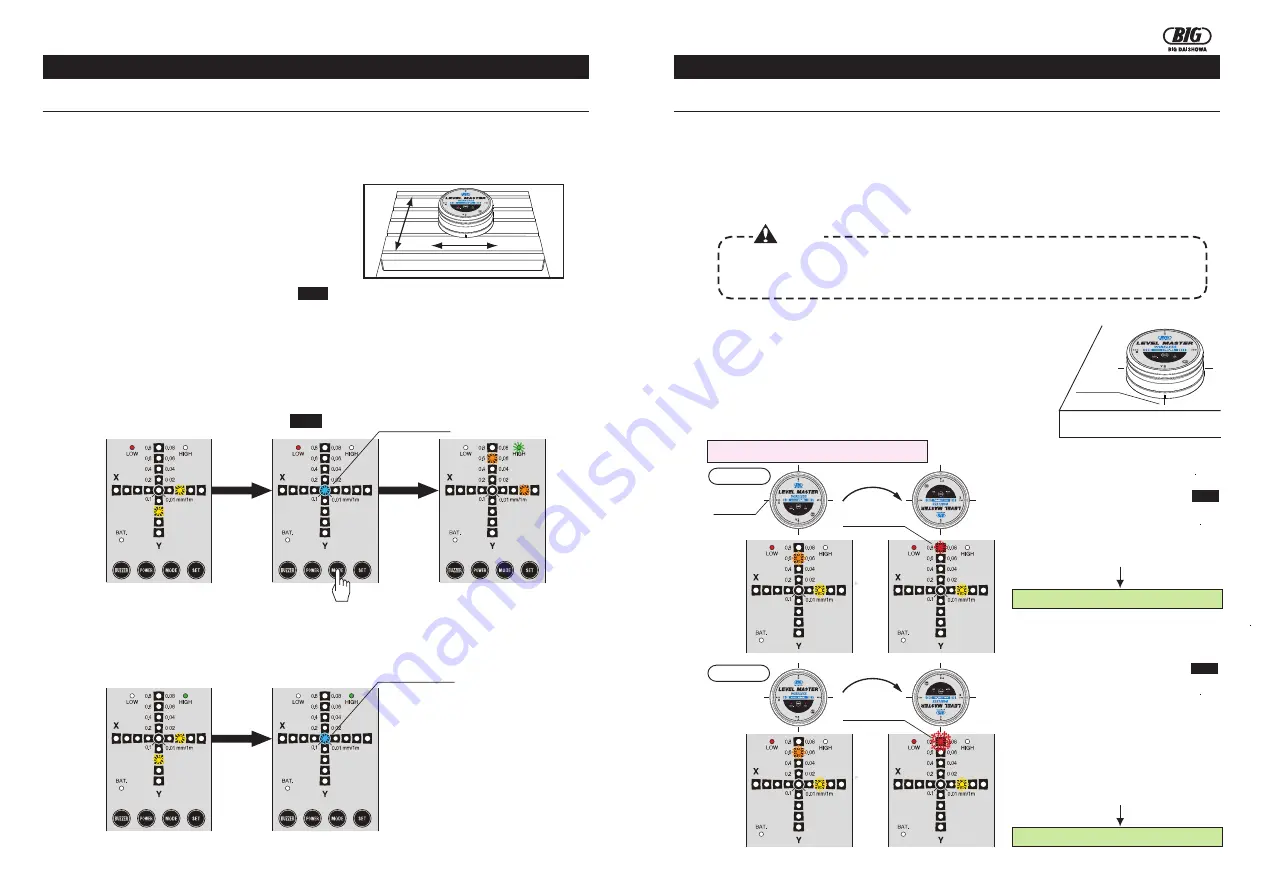

Turn

by180°

Turn

by180°

④

When power of the receiver is turned ON,

LOW

mode (inclination: 0.1mm - 0.8mm) is selected.

If the LED (red) in the 0.08. position blinks, inclination exceeds 0.8.

Levelling at

LOW mode

Change to

HIGH mode

Levelling at

HIGH mode

OPERATIONS

5.

OPERATIONS

5-1

.

Levelling operation

①

Remove oil, dirt, notches and marks from the machine table's surface and from the base of the device.

②

Place the device carefully on the reference surface

parallel to the X and Y axes.

X-axis

Y-axis

③

Push the POWER switch to turn ON the power of

Body/Receiver.

⑤

Adjust the level in order to turn on the LED (blue) of the central position. When the LED (blue) turns

on, the inclination is within 0.1.

When the inclination of one of the axes is adjusted within 0.1, the LED (blue) turns on and the buzzer

emits a sound [Beep, beep].

When the inclination of both axes is within 0.1, the LED (blue) turns on and the buzzer emits a

sound [Beep-beep-beep].

HIGH

⑥

Push the MODE switch to change to the mode.

⑦

Adjust the level in order to turn on the LED (blue) of the central position.

When the inclination of one of the axes is adjusted within 0.01, the LED (blue) turns on and the

buzzer emits a sound [Beep, beep]. When the inclination of both axes is within 0.01, the LED

(blue) turns on and the buzzer emits a sound [Beep-beep-beep].

Continuous LED (blue)

Continuous LED (blue)

4.

BEFORE USING THE DEVICE

BEFORE

USING THE DEVICE

4-1

.

Environmental settings

4-2

.

How to execute the zero adjustment

If there is a difference in the temperature between the storage location and the utilization location,

leave the device for a certain amount of time in the utilization location to perform the average

environmental settings (temperature, humidity).

When the Level Master

Wireless(Body/Receiver)

is turned on, depending on the utilization

environment and on the status of the reference surface measured, the level position may not be

always the "0" position (continuous blue LED). Execute every time the reference settings by

means of zero adjustment in accord with the utilization environment.

③

Push the POWER switch to turn ON the power

.

(Body/Receiver)

④

Execute the zero adjustment and the levelling checks following

the procedures

below.

②

Use as reference the line markers on the base of the Body and

mark 4 points in the X and Y directions on the reference surface

.

4 markings

①

Position the Body on the reference surface. When placing the

device, remove oil and dirt from its base and also remove notches,

oil and dirt from the reference surface of the precision plate.

(Example: If the difference in the temperature is 10

℃

, leave the device for 15~20 minutes.

)

Caution

How to check the levelling value in LOW mode

Case 2

Case 1

marking

Blinking LED (red)

Continuous LED (red)

②

The levelling value of both axes is

within 0.8 after turning the device by

180

°

.

①

The levelling value of the X and Y axes

is within 0.8 after switching to the

LOW

mode.

Go to P5

→

How to execute the zero adjustment in LOW mode

Go to P5

→

How to execute the zero adjustment in LOW mode

②

The levelling value of one of the axes

exceeds 0.8 after turning the device by

180

°

.

①

The levelling value of the X and Y axes

is within 0.8 after switching to the

LOW

mode.

③

Adjust the level of the reference

surface in order to obtain a levelling

value within 0.8

for both axes.