BL-CB33-0115 - 03-01-2018

2-1

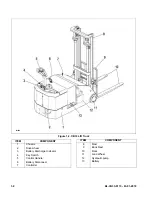

SECTION 2

OPERATION

2-1. GENERAL.

This section gives detailed operating instructions for

the CB33 lift truck. The instructions are divided into the

various phases of operations, such as operating lift,

driving, and stopping. Routine precautions are

included for safe operation.

2-2. OPERATING PRECAUTIONS.

WARNING:

Improper operation of the lift truck may

result in operator injury, or load and/or lift

truck damage. Observe the following

precautions when operating the CB33 lift

truck.

The following safety precautions must be adhered to

at all times.

• Do not operate this truck unless you have been

trained and authorized to do so.

• All warnings and instructions must be read and

understood before using the equipment.

• Equipment must not be altered in any way.

• Equipment must be inspected by a qualified person

on a regular basis.

• Do not exceed the rated capacity. Overloading may

result in damage to the hydraulic system and struc-

tural components.

• Be certain that the lifting mechanism is operating

smoothly throughout its entire height, both empty

and loaded.

• Be sure that mast is vertical - do not operate on a

slope.

• Be sure the truck has a firm and level footing.

• Avoid overhead wires and obstructions.

• Check for obstructions when raising or lowering the

lift carriage.

• Do not handle unstable or loosely stacked loads.

Use special care when handling long, high, or wide

loads to avoid tipping, loss of load, or striking

bystanders.

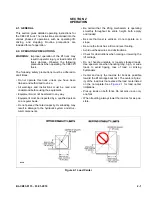

• Center and carry the load as far back as possible

toward the lift carriage back rest. The center-of-grav-

ity of the load must not exceed the load center listed

on the nameplate. See

for load center

limitations.

• Pick up loads on both forks. Do not pick up on only

one fork.

• When traveling, always lower the load as far as pos-

sible.

Figure 2-1 Load Center

R3814

Summary of Contents for CB33

Page 9: ...BL CB33 0115 03 01 2018 2 3 Figure 2 2 Sample of Operator Check List R6479...

Page 12: ...2 6 BL CB33 0115 03 01 2018 NOTES...

Page 18: ...3 6 BL CB33 0115 03 01 2018 NOTES...

Page 38: ...4 20 BL CB33 0115 03 01 2018 NOTES...

Page 44: ...5 6 BL CB33 0115 03 01 2018 NOTES...

Page 46: ...6 2 BL CB33 0115 03 01 2018 Figure 6 1 Drive Assembly DP_0004...

Page 48: ...7 2 BL CB33 0115 03 01 2018 Figure 7 1 Drive Assembly DP_0004...

Page 49: ...BL CB33 0115 03 01 2018 7 3 Figure 7 2 Load Wheels DP_0007...

Page 50: ...7 4 BL CB33 0115 03 01 2018 NOTES...

Page 52: ...8 2 BL CB33 0115 03 01 2018 Figure 8 2 Elevation System Telescopic DP_0008...

Page 54: ...8 4 BL CB33 0115 03 01 2018 Figure 8 3 Mast Three Stage Mast DP_0009...

Page 56: ...8 6 BL CB33 0115 03 01 2018 NOTES...

Page 58: ...9 2 BL CB33 0115 03 01 2018 Figure 9 1 Hydraulic System DP_0018...

Page 60: ...9 4 BL CB33 0115 03 01 2018 Figure 9 3 Elevation System Telescopic DP_0008...

Page 66: ...9 10 BL CB33 0115 03 01 2018 Figure 9 8 Secondary Lift Cylinder Three Stage Mast DP_0012...

Page 69: ...BL CB33 0115 03 01 2018 9 13 Figure 9 10 Tilt Cylinder DP_0016...

Page 70: ...9 14 BL CB33 0115 03 01 2018 NOTES...

Page 72: ...10 2 BL CB33 0115 03 01 2018 Figure 10 1 Electrical System R6478 DP_0022...

Page 73: ...BL CB33 0115 03 01 2018 10 3 Figure 10 2 Electrical Panel R6478 DP_0023...

Page 75: ...BL CB33 0115 03 01 2018 10 5 Figure 10 3 Transmission Motor Brake Assembly DP_0004...

Page 76: ...10 6 BL CB33 0115 03 01 2018 NOTES...

Page 77: ...BL CB33 0115 03 01 2018 11 1 SECTION 11 OPTIONAL EQUIPMENT...

Page 78: ...11 2 BL CB33 0115 03 01 2018 NOTES...

Page 80: ...12 2 BL CB33 0115 03 01 2018 Figure 12 1 Steering System DP_0001...

Page 82: ...12 4 BL CB33 0115 03 01 2018 Figure 12 1 Steering System Continued DP_0001...

Page 84: ...12 6 BL CB33 0115 03 01 2018 Figure 12 2 Control Head DPP_0002...

Page 86: ...12 8 BL CB33 0115 03 01 2018 Figure 12 3 Control Head when Side Shift option DP_0035...

Page 88: ...12 10 BL CB33 0115 03 01 2018 Figure 12 4 Drive System DP_0003...

Page 90: ...12 12 BL CB33 0115 03 01 2018 Figure 12 5 Drive Assembly Used up to serial S2410419 DP_0004...

Page 94: ...12 16 BL CB33 0115 03 01 2018 Figure 12 7 Drive Assembly Used from serial 325130601 DP_0032...

Page 104: ...12 26 BL CB33 0115 03 01 2018 Figure 12 10 Compartment DP_0005...

Page 106: ...12 28 BL CB33 0115 03 01 2018 Figure 12 11 Frame DP_0006...

Page 108: ...12 30 BL CB33 0115 03 01 2018 Figure 12 11 Frame Continued DP_0006...

Page 110: ...12 32 BL CB33 0115 03 01 2018 Figure 12 12 Load Wheels DP_0007...

Page 112: ...12 34 BL CB33 0115 03 01 2018 Figure 12 13 Elevation System Telescopic DP_0008...

Page 114: ...12 36 BL CB33 0115 03 01 2018 Figure 12 13 Elevation System Telescopic Continued DP_0008...

Page 116: ...12 38 BL CB33 0115 03 01 2018 Figure 12 14 Elevation System Three Stage Mast DP_0009...

Page 118: ...12 40 BL CB33 0115 03 01 2018 Figure 12 14 Elevation System Three Stage Mast Continued DP_0009...

Page 124: ...12 46 BL CB33 0115 03 01 2018 Figure 12 16 Lift Carriage Three Stage Mast DP_0014...

Page 126: ...12 48 BL CB33 0115 03 01 2018 Figure 12 17 Side Shift Assembly DP_0034...

Page 128: ...12 50 BL CB33 0115 03 01 2018 Figure 12 18 Chain Assembly DP_0017...

Page 134: ...12 56 BL CB33 0115 03 01 2018 Figure 12 21 Hydraulic System Used with Side Shift DP_0036...

Page 136: ...12 58 BL CB33 0115 03 01 2018 Figure 12 22 Tilt System DP_0015...

Page 138: ...12 60 BL CB33 0115 03 01 2018 Figure 12 23 Lift System Telescopic Not with Side Shift DP_0019...

Page 140: ...12 62 BL CB33 0115 03 01 2018 Figure 12 24 Lift System Telescopic With Side Shift DP_0037...

Page 146: ...12 68 BL CB33 0115 03 01 2018 Figure 12 26 Lift Cylinder Telescopic DP_0010...

Page 148: ...12 70 BL CB33 0115 03 01 2018 Figure 12 27 Free Lift Cylinder Three Stage Mast DP_0011...

Page 150: ...12 72 BL CB33 0115 03 01 2018 Figure 12 28 Secondary Lift Cylinder Three Stage Mast DP_0012...

Page 156: ...12 78 BL CB33 0115 03 01 2018 Figure 12 31 Pump and Motor Not when Side Shift DP_0021...

Page 158: ...12 80 BL CB33 0115 03 01 2018 Figure 12 32 Pump and Motor When Side Shift DP_0039...

Page 160: ...12 82 BL CB33 0115 03 01 2018 Figure 12 33 Electrical System ELECTRICAL SYSTEM DP_0022...

Page 162: ...12 84 BL CB33 0115 03 01 2018 Figure 12 34 Electrical Panel DP_0023...

Page 168: ...12 90 BL CB33 0115 03 01 2018 Figure 12 37 Wiring Cables DP_0025...

Page 170: ...Big Lift LLC...