5

SAFETY SYMBOLS

WARNING

and

CAUTION

are both signal words intended to alert the viewer to

the existence and relative degree of a hazard. They are both preceded by a safety

alert symbol consisting of an exclamation mark enclosed by a triangle.

A

Warning

indicates a hazard which could result in injury or death if proper pre-

cautions are not taken.

A

Caution

indicates a reminder of routine safety practices.

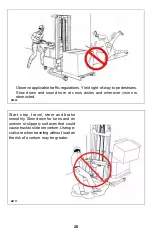

A prohibition slash (circle with diagonal slash through it) indicates a procedure or

action that should

not

be performed under any circumstances, as both personal

injury and/or damage to equipment will result.

GENERAL DESCRIPTION

The Big Lift LLC Straddle trucks utilize

the straddle leg configuration, which

normally straddles the load.

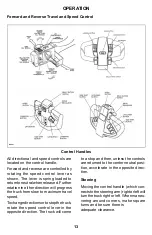

Control for steering, braking, forward

and reverse travel, horn and speed con-

trol are all located on the control handle.

All trucks feature an automatic high

speed cut-off circuit which locks out

high speed when the forks are elevated.

Trucks in this series may vary in load

capacity, battery arrangement, instru-

mentation and lift/lower controls,

depending on model and options. The

forks may be rigid or adjustable. One

model has a reach and tilt mechanism

which extends the forks toward the load,

then retracts and tilts back the forks for

transporting the load.

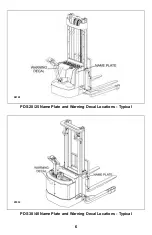

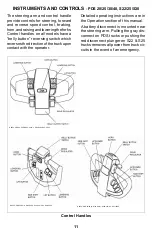

NAME PLATE AND WARNING DECAL

Warning decal locations may vary

between models, but normally they are

near the steering arm within sight of the

operator. The name plate is mounted on

the truck frame or mast. See illustration

on next pages

If the name plate or warning decal are

l o s t o r d a m a g e d t h e y s h o u l d b e

replaced immediately. Have your

supervisor or the designated authority

contact Big Lift LLC Authorized Dealer

for replacement.

The name plate shows the model num-

ber, serial number, and truck type. Bat-

tery type, with voltage and minimum

weight, is shown along with information

on the load capacity and load center.

The warning decal contains warnings

which also appear, with illustrations, in

the Operation section of this manual.