6

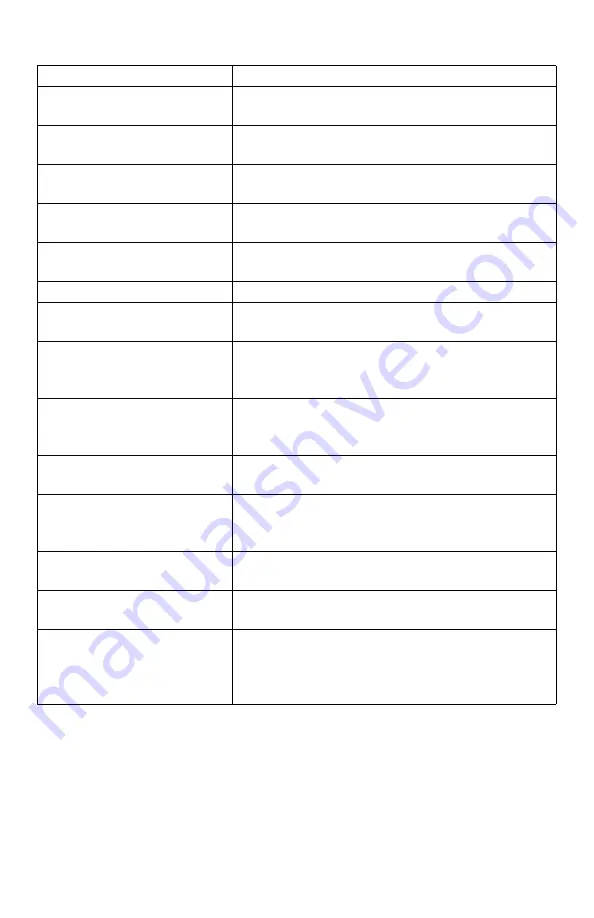

Operator Checks

ITEM

PROCEDURE

Transmission and hydrau-

lic systems

Check for signs of fluid leakage.

Forks

Check for cracks and damage and that they

are properly secured.

Chains, cables and hoses

Check that they are in place, properly secured

and not damaged or leaking.

Guards and load backrest

Check that safety guards are in place, prop-

erly secured and not damaged.

Safety signs

Check that warning labels, data plate, etc., are

in good condition and legible.

Horn

Check that horn sounds when operated.

Steering

Check for binding or looseness in steering

arm when steering.

Travel controls

Check that speed controls on control handle

operate in all speed ranges in forward and

reverse and that belly button switch functions.

Wheels

Check drive wheel for cracks or damage.

Move truck to check load wheels and casters

for freedom of rotation.

Hydraulic controls

Check operation of lift, lower and reach to

their maximum positions.

Brakes

Check that brakes actuate when steering arm

is raised to upright position, and when lowered

to horizontal position.

Deadman/Parking brake

Check that steering arm raises to upright posi-

tion when released and brake applies.

Battery disconnect

Check that battery can be disconnected and

reconnected. Check for connector damage.

High speed limit switch

Allow for enough space to operate truck in

high speed. Elevate forks approximately two

feet, then test drive truck to check if high

speed is cut out.

Summary of Contents for PDSR

Page 2: ......

Page 15: ...13 Do not carry passengers Keep feet clear of truck and always wear foot protection ...

Page 23: ......

Page 24: ...Big Lift LLC ...