9

Turning

1.

Release the floor lock.

NOTE:

Turning and maneuvering the lift

truck is made easier if the truck is

in motion.

2.

Begin rolling the truck and simultane-

ously apply side pressure to the steer-

ing handle to cause the caster wheels

to swivel.

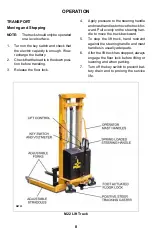

OPERATING THE LIFT

WARNING:

Check the space above

the load on the forks to

ensure that the load will

not strike any obstruction

while being raised.

1.

Turn the key switch ON.

2.

To raise the forks, pull the lift con-trol

back and hold until the forks reach the

desired height. The forks will raise at a

fixed speed. Return the lift control to

the neutral position.

3.

To lower the forks, push the lift control

forward and hold until the forks reach

the desired level. The lowering speed

can be controlled by the lever. Return

the lift control to the neutral position.

LOADING AND UNLOADING

1.

Move the truck to the location where

the load is to be picked up.

2.

Adjust the forks to the maximum prac-

tical width to support the load.

3.

Raise the forks to the desired height for

entry under the load.

4.

Move the lift truck into position so that

the forks are centered under the load.

5.

Move the lift truck forward to place the

load as far back as pos-sible toward the

lift carriage. Raise the forks to lift the

load.

CAUTION:

To avoid spilling the load,

move slowly and use extra

caution when turning.

6.

Move the lift truck backward from the

loading position.

7.

When the load is clear of its rack, lower

the load, leaving enough floor clear-

ance to maneuver the truck.

8.

Push or pull the truck carefully to the

area where the load is to be placed.

9.

Align the lift truck with its new position.

10. Raise the forks to the desired height

and slowly move the lift truck into posi-

tion for off-loading.

CAUTION:

The load must rest squarely

on its rack when it is low-

ered into position.

11. When the load is in position, lower the

forks until the pallet rests on its rack and

the forks are free.

12. Slowly move the lift truck back-ward,

checking that the forks do not catch on

the pallet or rack.

13. Lower the forks when they are clear.

14. Proceed to move the next load.

PARKING

When finished with moving loads, lower

the forks and move the lift truck to its

maintenance or storage area. Engage the

floor lock. Turn off the key switch. Charge

the battery if required.