WWW.BIGASSFANS.COM © 2020 DELTA T LLC ALL RIGHTS RESERVED.

2

ASSEMBLY AND SETUP

IMPORTANT

Carefully examine the carton for damage before opening. If the carton is damaged, notify the shipping

company immediately.

Install Casters (Cold Front 300 only):

1. Locate the package of four (4) casters and sixteen (16) bolts and remove from box.

2. Lay box on its side and carefully open bottom of box. DO NOT STAND BOX UPSIDE DOWN.

3. Install the four casters using the bolts.

4. Stand cooler up on casters and remove box.

The cooler has been factory tested and is ready to use. Place the cooler on level ground with the casters locked

to prevent inadvertent movement.

Connecting the water supply

The cooler comes equipped with a garden hose water source connection. Use a standard garden hose (not

provided) to connect the water supply to the cooler.

CAUTION

Do not connect to any water source where water pressure exceeds 120 PSI (8 bar/827 kPa). This will cause

permanent damage to the cooler.

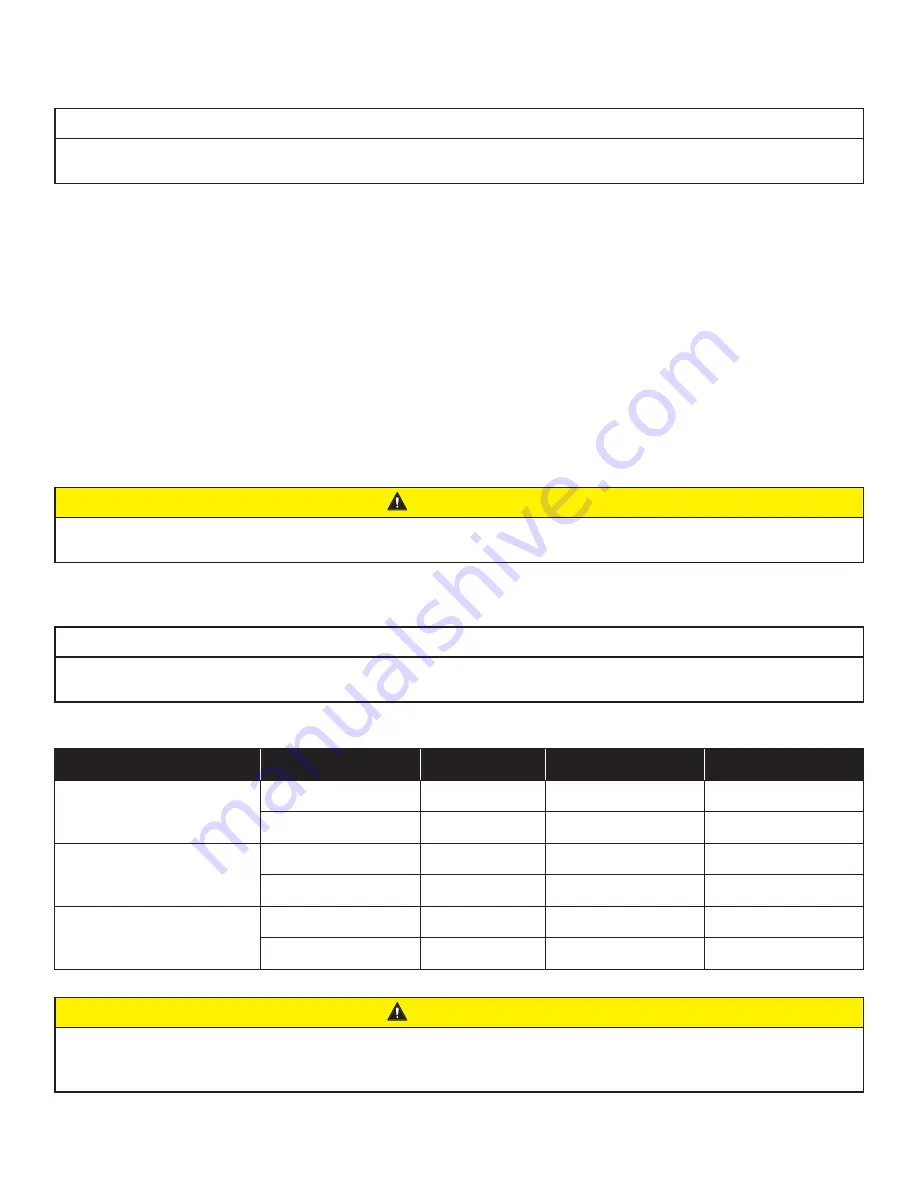

Connecting the electrical supply

IMPORTANT

The cooler should be plugged into a fused or breaker-protected circuit. Refer to the table for circuit size

requirements. Cold Front 500 models cannot be connected to a GFCI outlet.

Amperage and Circuit Requirements

Model

Volts +/- 10%

Frequency

Min. Circuit Size

Running Amps

Cold Front 300

120 V

60 Hz

15 A

4.1 A

220/230 V

50/60 Hz

10 A

1.8 A

Cold Front 400

120 V

60 Hz

15 A

8.0 A

220/230 V

50/60 Hz

10 A

5.0 A

Cold Front 500

120 V

60 Hz

25 A

16.5 A

220/230 V

50/60 Hz

15 A

8.6 A

CAUTION

Do not exceed the amperage ratings of the extension cord. Undersized extension cords create excessive

drops in voltage, causing the electric motor to generate excess heat. This results in inefficient motor

operation and premature motor failure and will void the warranty.