WWW.BIGASSFANS.COM © 2021 DELTA T LLC ALL RIGHTS RESERVED.

59

SECTION 14: GENERAL

SPECIFICATIONS

14.1 Material Specifications

14.1.1 Reflectors

0.024 Aluminum

14.2 Heater Specifications

14.2.1 Ignition Fully automatic, three-try,

direct spark, electronic ignition control,

100% safety shut-off

14.3 Suspension Specifications

Hang heater using materials with a minimum working

load of 75 lb (33 kg). See “FIGURE 11: Critical Hanger

Placement” on page 13.

14.4 Controls Specifications

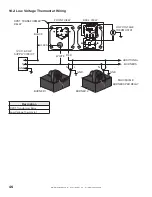

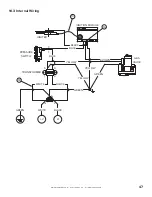

Time switches, thermostats, etc. can be wired into

the electrical supply. External controls supplied as an

optional extra.

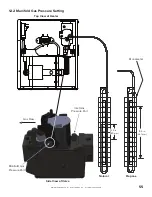

GAS PRESSURE AT MANIFOLD:

Natural Gas: 3.5” wc

LP Gas: 10.5” wc

PIPE CONNECTION:

1/2” NPT

DIMENSIONS:

Vent Connection Size: 4” (10 cm)

Outside Air Connection Size: 4” (10 cm)

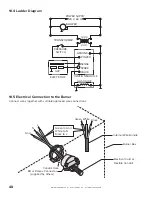

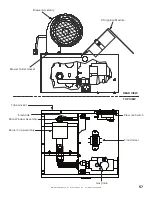

Refer to figure above for dimensional information.

ELECTRICAL RATING (ALL MODELS):

120 V, 60 Hz, 1 A (run)

GAS INLET PRESSURE:

Natural Gas:

IRH 80, 125, and 150: 4.6” wc Minimum

IRH 200: 5.0” wc Minimum

14.0” wc Maximum

LP Gas:

11.0” wc Minimum

14.0” wc Maximum

Model

Heat Input Rate

Minimum Length (A)

Recommended

Minimum Mounting Height*

Space

Spot

IRH 80

80,000 BTU/h

20 ft (6 m)

12–15 ft (3.6–4.5 m)

11 ft (3.3 m)

IRH 125

125,000 BTU/h

30 ft (9 m)

15–20 ft (4.5–6 m)

15 ft (4.6 m)

IRH 150

150,000 BTU/h

40 ft (12 m)

20–25 ft (6–7.6 m)

20 ft (6.1 m)

IRH 200

200,000 BTU/h

50 ft (15 m)

25 ft (7.6 m)

25 ft (7.6 m)

* See “SECTION 3: CLEARANCES TO COMBUSTIBLES” on page 4.

12.5 in.

(32 cm)

12.5 in.

(32 cm)

End View

Side View

Reflector

Burner Tube

11 in.

(28 cm)

Minimum Length A

Turbulator

Summary of Contents for IRH

Page 4: ......