BIL-JAX 3632T

The hydraulic power unit uses a 24-Volt, one

horsepower DC motor to drive the hydraulic pump.

The DC motor is powered by four 6-Volt DC, 245

Amp-hour deep charge batteries connected in

series. An automatic onboard battery charger is

provided with standard models for recharging the

batteries at the end of each work period.

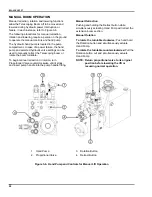

Two control panels (Figure 2-2) use pushbutton

switches and hydraulic valves to control the direction

and speed of boom lift and rotation. One set of

operator controls is provided for ground operation

and another set is provided for operation from the

platform. Elevation and rotation controls are

operational only when the outriggers are correctly

extended and the moving boom section is within a

programmed safe operating zone.

Figure 2-2. Boom Lift Control Panel (Ground)

The ground and platform control panels include

CHOKE

and

START

buttons for use with boom models

equipped with an optional DC/gasoline hybrid

generator for continuous duty. Battery condition

indicators show the charge state of the batteries.

When pressed, a

STOP

button at each control panel

immediately stops all boom motions. The ground

control panel includes a lighted text window that

displays the present operating status or an existing

error condition. The platform control panel includes a

horn button that sounds an audible alarm when

pressed.

Boom elevation, extension and rotation speeds are

selected from low to high by

SPEED

buttons. The lift

and extension cylinders have load-holding valves in

the base of each cylinder in case of a hydraulic hose

failure.

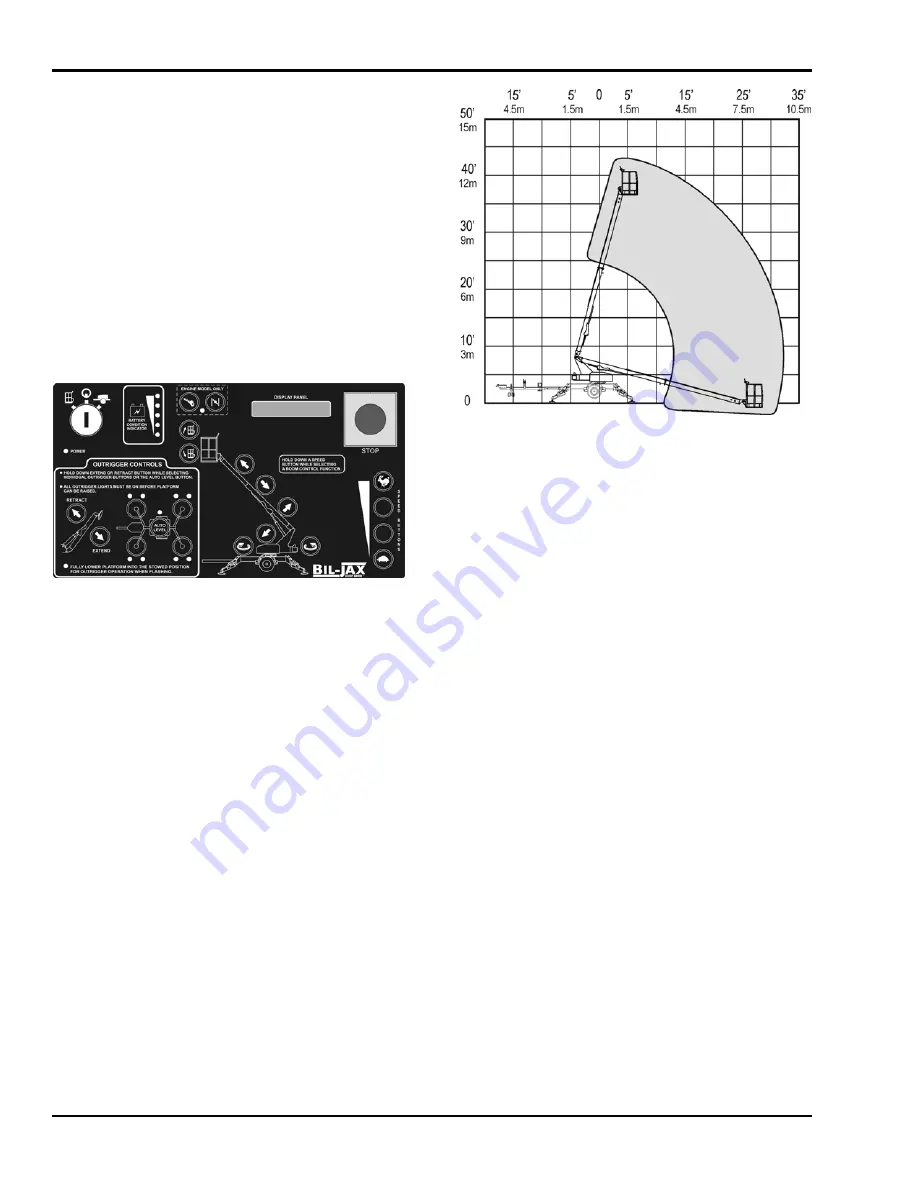

Only one boom motion is permitted at a time and

only as long as the boom is within the safe operating

zone (Figure 2-3). When a selected boom motion

exceeds a safe operating limit, the boom motion

ceases and another boom motion must be selected

within the safe operating zone.

Figure 2-3. Range of Motion

Outrigger load sensing switches and level sensing

interlocks prevent all platform boom operations until

the four outriggers are properly extended, the trailer

is level and the full weight of the boom lift is loaded

onto the outriggers. A boom-raised interlock

prevents outrigger operation until the platform boom

is fully lowered to the stowed position.

Safety devices prevent the boom from retracting

suddenly in the event of a hydraulic hose or system

failure.

It is strongly recommended that no one

adjust or tamper with these safety devices. If service

is required, please notify Bil-Jax for instructions.

Each cylinder rod is fully immersed in oil to prevent

rust or corrosion of the cylinders during storage. It is

important that the cylinder rods be kept clean and

undamaged for the protection of the cylinder head

packings.

In the event of power loss, control system failure or

other malfunction, all boom movement functions may

be accomplished by manual operations.

Manual lowering of the platform is performed by

actuating a valve plunger found on the base of the

boom lift cylinder. Pulling and holding the valve

plunger retracts the boom lift cylinder. The boom

may need to be rotated to a clear area before

lowering.

Manual boom retraction and turntable rotation are

accessed inside the pump compartment. The hand

pump and selected valves on the hydraulic pump

unit are used for these functions.

10

Summary of Contents for 3632T

Page 1: ...OPERATOR S MANUAL T 134 98 B33 01 0089 3632T ...

Page 42: ...BIL JAX 3632T 40 ...

Page 46: ...BIL JAX 3632T 44 ...