BC26 HYDRO-DRIVE Operator’s Manual

Part No 501533

10

501533_B_HI

NOTE

: Items in ( ) can be referenced in the Parts Illustrations and Parts Lists on pages 14-21.

BLADE

SHARPENING

AND

REMOVAL

READ

all safety instructions before servicing unit.

1.

Disconnect spark plug wire.

2.

Lift and support front of unit to allow access to underside.

UNIT IS HEAVY

. Make sure support is adequate to support weight of machine.

3.

Block blade to prevent it from rotating during removal.

4.

Remove blade bolt (item 23), and friction washer (item 39).

5.

Remove blade (item 2) and install replacement blade.

NOTE

: When sharpening blade make sure to sharpen all cutting

edges. If the lock nut is removed and replaced more than once, it should be replaced with a new lock nut (P/N 8160009).

When replacing the blade use BILLY GOAT Industries PN 501224 only.

6.

Attach new blade with new blade bolt (item 23), and new friction washer (item 39) removed earlier included with your

new blade.

NOTE

: Inspect fasteners for wear and replace if necessary.

7.

Torque blade bolt to 40 ft-lbs.

8.

Reconnect spark plug wire.

BLADE

DRIVE

BELT

TENSION

NOTE

:

The Blade Drive belt is under constant tension by the idler arm on the deck.

DISCONNECT

spark plug wire before servicing unit.

1.

Disconnect spark plug wire.

2.

Loosen four screws (item 27) holding belt deck cover (item 29) and remove the cover.

3.

Examine condition of belt and amount of tension on belt.

4.

If the idler is not providing enough tension inspect the spring (item 50) attaching it to the spindle base. If not enough

tension is being put on the arm, replace the spring.

5.

Replace engine base door (item 29) and secure with screws removed earlier.

6.

Reconnect spark plug wire.

7.

Check belt tension by operating unit under conditions that caused belt slippage. If belt continues to slip it may require

replacement before operation may continue.

BLADE

CLUTCH

ADJUSTMENT

DISCONNECT

spark plug wire before servicing unit.

DISCONNECT

spark plug wire before servicing unit.

If clutch continues to slip or squeal, do not operate equipment until adequate adjustment or repair

has been performed. Improper adjustment can cause clutch to overheat and slip, greatly reducing

performance and clutch life.

1.

Disconnect spark plug wire.

2.

As the clutch/brake wears or begins slipping or squealing, adjustment may be

required to maintain proper cable tension and clutch engagement. A properly

adjusted blade clutch should require 10 lbs. of force to depress the end of the

clutch lever. The blade clutch cable spring should stretch 1/4” to 3/8” (6.4-9.5

mm).

3.

Adjust cable tension by tightening or loosening cable adjustment nut on rear

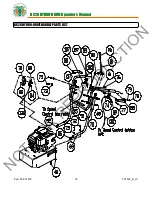

of engine base (see

Fig. 8

). Be sure to leave enough slack in cable to allow

blade brake to engage.

4.

Reconnect spark plug wire.

Fig. 8

NOT

FOR

REPRODUCTION